In What Application scenario you need use the Hydrostatic Pressure Testing Equipment?

The static Hydrostatic Pressure Testing of pipes is mainly used to assess the pressure resistance and sealing performance of pipes under constant pressure, and its application scenarios cover multiple fields:

Gas Pipeline Safety Testing: Used for strength verification of underground polyethylene gas pipeline systems, simulating actual working conditions to test the pressure resistance of the pipeline, ensuring gas transportation safety.

Plastic Pipe Performance Testing: Applicable to long-term pressure resistance testing of thermoplastic pipes such as PE, PVC, and PP-R, conducted according to the national standard ISO 1167 to evaluate their cracking resistance and sealing performance.

Automotive Component Testing: Can determine the pressure endurance time and burst pressure values of automotive hoses, rubber hoses, air conditioning pipes, etc., ensuring the safety of automotive hydraulic systems.

Metal Pipe Verification: Conduct macro strength and sealing tests on metal pipes such as steel and aluminum pipes to ensure the stability of metal pipelines under high-pressure environments.

Other Material Testing: Applicable to pressure resistance evaluation of non-metallic materials such as rubber hoses and geothermal pipes, by controlling pressure and temperature parameters to simulate actual use scenarios.

What Data and Result you can get from the Hydrostatic Pressure Testing?

Pressure Resistance Performance

By simulating the long-term pressurized environment of pipes, the creep resistance and durability of the pipe material are assessed. According to standard requirements, the pressure values are adjusted based on the designed pressure rating of the pipe (e.g., SDR11, SDR17) and the test temperature (20°C, 80°C); for instance, the test pressure for PE100 pipes at 80°C is generally 4.6MPa.

Temperature Control

The tests need to be conducted in a constant temperature environment, with temperature fluctuations controlled within ±1°C. If the temperature deviation exceeds this range, it may lead to invalid test results or data errors. For example, a temperature increase of 2°C can accelerate the pipe's creep, resulting in a shorter test duration.

Failure Modes

Record the rupture time and failure mode of the pipe material (ductile fracture or brittle fracture), and analyze the material properties through features such as the elongation rate and cross-sectional flatness. For example, brittle fractures are often caused by processing defects or material degradation.

Data Recording

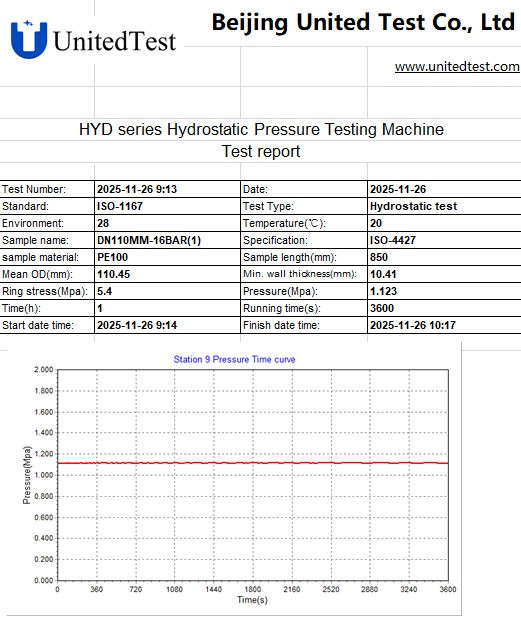

Real-time acquisition of pressure, time, and temperature parameters in synchronized curves is necessary, with a sampling frequency of ≥1Hz. Data should include original waveform recordings and photographs of failure modes. Manual recording can easily lead to transcription errors, so it is recommended to use an automated acquisition system.

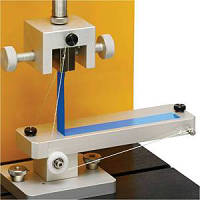

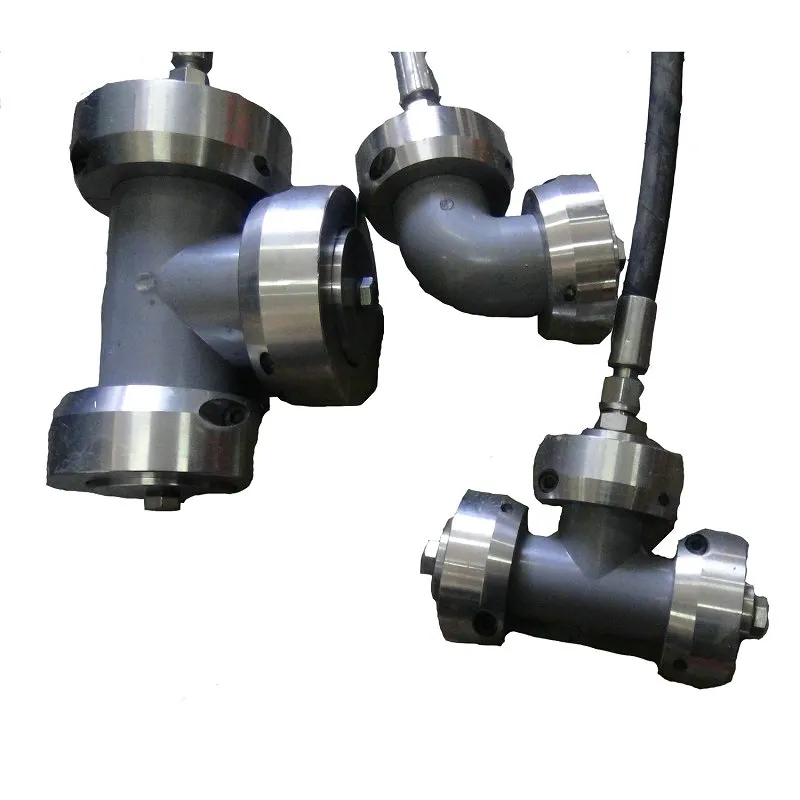

Why Choose UnitedTest Hydrostatic Pressure Testing Machine and the feature of UnitedTest testing machine?

HYD series Pipeline hydrostatic pressure testing machine is designed according to ISO 1167, ASTM D1598, ASTM D1599. It’s mainly used to test the plastic pipeline, compound pipeline, such as PP-R, PP-B, PP-A, PVC, PE, PE-X etc. Under a stipulated constant hydrostatic pressure force, keeping provision time; or inside the pipe, apply a constant and rapid hydraulic pressure to make the specimen broken in a short period time, check the max. pressure force, then calculate the ring stress. This tester is necessary equipment for plastic pipe manufacturer.