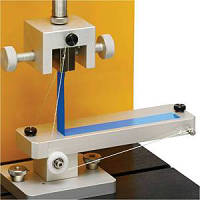

Puncture tests play a pivotal role in material R&D, quality

control, and product certification across multiple industries, as they

directly relate to product safety, durability, and compliance with

regulatory requirements. Below are key application scenarios by

industry:

Packaging Industry

Food

packaging: Test the puncture resistance of plastic films, aluminum foil

laminates, and paperboards to prevent packaging damage during

transportation and storage, ensuring food freshness and hygiene.

Medical

packaging: Evaluate the puncture performance of sterile packaging

materials (e.g., medical film, blister packs) to resist accidental

penetration and maintain sterility.

Textile & Apparel Industry

Protective

clothing: Test the puncture resistance of fabrics used in military

uniforms, industrial workwear, and medical gowns to shield against sharp

objects (e.g., needles, shrapnel).

Daily textiles: Assess the

durability of upholstery fabrics, carpet materials, and sportswear to

ensure they withstand daily wear and tear.

Automotive & Aerospace Industry

Automotive

interiors: Evaluate the puncture resistance of seat fabrics, door

panels, and floor mats to ensure long-term use without damage.

Aerospace

materials: Test the puncture performance of composite components (e.g.,

aircraft interior panels, cargo compartment liners) to meet strict

safety standards.

Construction & Building Materials

Waterproof

materials: Test the puncture resistance of waterproof membranes, roof

tiles, and geomembranes to prevent damage from gravel, roots, or

construction tools, ensuring structural waterproofing.

Building

panels: Assess the puncture performance of gypsum boards, fiber cement

boards, and decorative panels to ensure structural integrity.

Electronic & Consumer Goods Industry

Flexible

electronics: Test the puncture resistance of flexible display screens,

wearable device casings, and battery diaphragms to ensure reliability

during use.

Plastic products: Evaluate the puncture strength of

plastic casings, toys, and household appliances to meet safety standards

and avoid potential hazards.