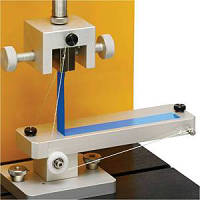

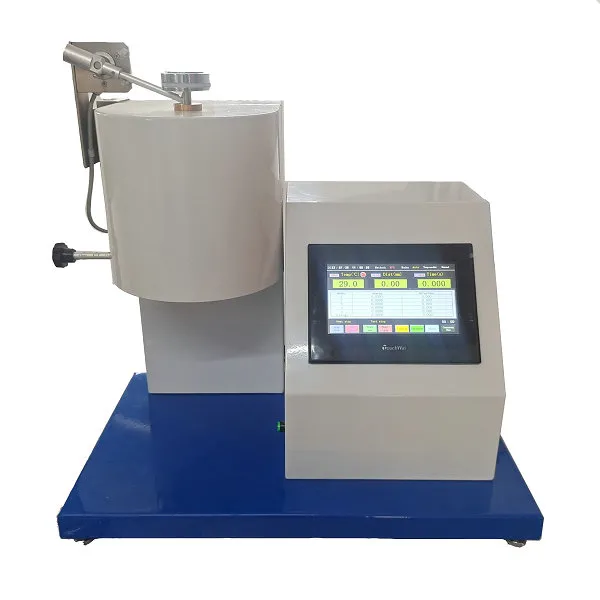

Principle of measurement of melt flow rate tester

The heating material flow through an orifice at a prescribed temperature and load. It provides a means of measuring flow of a melted material which can be used to differentiate grades as with polyethylene, or determine the extent of degradation of the plastic as a result of molding. Degraded materials would generally flow more as a result of reduced molecular weight, and could exhibit reduced physical properties. Typically, flow rates for a part and the resin it is molded from are determined, and then a percentage difference is calculated. Alternatively, comparisons between "good" parts and "bad" parts may be of value.

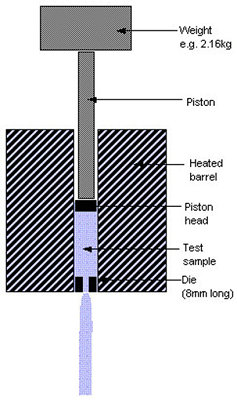

This instrument employs a mass method measurement principle, allowing the plastic melt to flow through a standard die (with a diameter of 2.095±0.005mm and a length of 8±0.01mm, made of tungsten carbide) at a preset temperature. It records the amount of melt that flows out within 10 minutes (measured in g/10min).

Standardized test conditions are achieved by controlling the temperature (usually at the material's melting temperature, such as 190°C for PE, 230°C for PP), load (adjusting the weight of the weights), and shear rate (which is related to the die size).

Why the melt flow index test is important for polymer material?

The melt flow rate tester characterizes the viscous flow properties of thermoplastic materials by measuring the mass or volume of the material that flows through a standard die over a period of 10 minutes at a specified temperature and load. Its core principle is to convert the flow resistance of the plastic melt into quantifiable numerical indicators, which are used to evaluate the processing flow properties of the material.

Main application reasons of melt flow index test?

1, Assessing Material Flowability

The MFR measures the melt mass that flows through a standard die (diameter 2.095mm, length 8.000mm) within 10 minutes, directly reflecting the material's flowability under specific shear conditions. A higher value (e.g., the MFR of LDPE typically ranges from 1-20g/10min) indicates better flowability; conversely, a lower value (e.g., the MFR of HDPE is mostly 0.1-10g/10min) indicates poorer flowability.

2, Quality Control and Production Optimization

In plastic processing, the MFR can serve as a basis for adjusting formulations and optimizing processes. For example, by adjusting temperature, load, or shear rate, material formulations can be quickly screened or processing parameters improved, thereby enhancing production efficiency.

Other name:

Melt flow index testing equipment; melting flow indexer; melt indexer iso 1133; digital melt flow rate tester; quality melt flow index testing machine; melt flow index astm; plastic Melting Flow Index tester