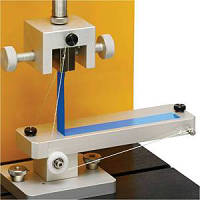

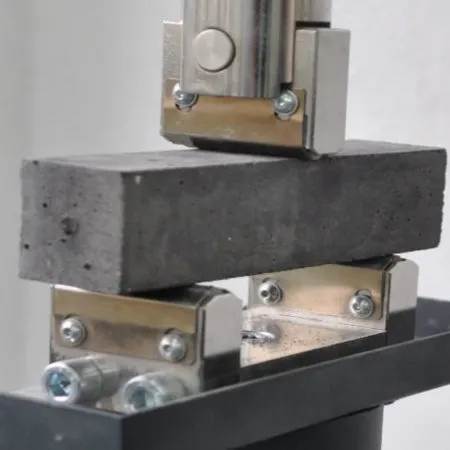

Fixtures are core components of flexural testing machines, responsible for supporting the specimen and transmitting the test load stably and accurately. Their design directly affects the reliability and repeatability of test results. UnitedTest, as a professional provider of mechanical testing equipment, integrates high-precision fixture technology into its flexural testing systems to adapt to diverse material requirements.

Key Fixture Components

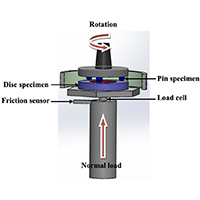

Support rollers: Used to support the specimen, ensuring it can rotate freely during bending to avoid additional shear stress. The rollers are typically made of high-hardness alloy steel or tungsten carbide to resist wear and deformation.

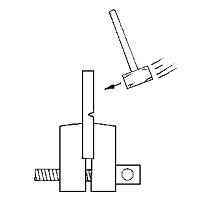

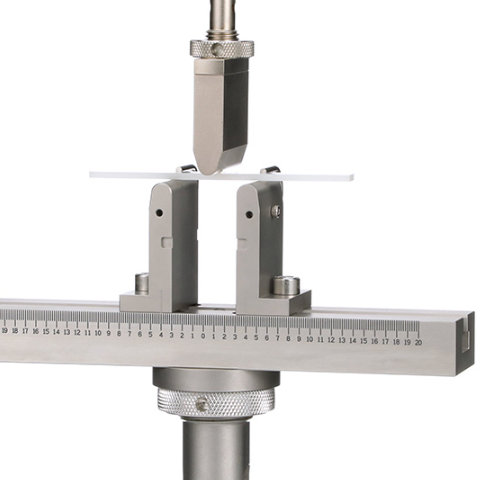

Loading nose: Applies the test load to the specimen. For three-point bending, it is a single cylindrical nose; for four-point bending, it consists of two parallel rollers. The surface is precision-ground to ensure uniform load distribution.

Adjustment mechanisms: Include adjustable support spans and loading positions to accommodate different specimen sizes (length, width, thickness) as specified by test standards. Advanced fixtures feature digital adjustment for high positioning accuracy.

Clamping auxiliary parts: For flexible or thin specimens (e.g., films, thin plates), anti-slip pads or side clamps are added to prevent specimen displacement during testing.

Fixture Material Requirements

Fixtures must have higher hardness and rigidity than the tested specimens to avoid fixture deformation affecting test data. Common materials include high-carbon steel, stainless steel, and ceramic, with surface treatments such as quenching and chrome plating to enhance wear resistance and corrosion resistance.