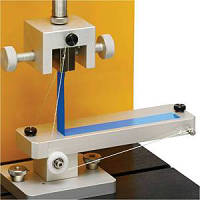

The shear test is a critical mechanical property evaluation method that assesses a material’s ability to resist tangential forces that cause adjacent internal material layers to slide past each other. Unlike tensile or compression tests that focus on axial loads, shear tests simulate real-world scenarios where materials endure parallel, opposing forces—such as bolted joints under load, adhesive bonds, or structural components subjected to lateral stress. Key indicators derived from this test include shear strength, shear modulus, and shear strain at failure, which are essential for ensuring the structural integrity and reliability of materials and components. UnitedTest, a professional provider of mechanical testing equipment, offers high-precision shear testing systems with customized fixture solutions, catering to diverse industrial material requirements and ensuring accurate, repeatable test results.

Core Definition & Principle

A shear test involves applying a controlled tangential load to a specimen along a predefined shear plane until the material fractures or undergoes significant plastic deformation. The test focuses on measuring two core parameters:

Shear strength: The maximum shear stress a material can withstand before failure, which is critical for evaluating the load-bearing capacity of joints, fasteners, and structural components.

Shear modulus (modulus of rigidity): The ratio of shear stress to shear strain within the elastic limit, reflecting the material’s resistance to elastic deformation under shear forces.

During the test, a shear stress-shear strain curve is generated, which also helps analyze the material’s ductility under shear—whether it fractures suddenly (brittle materials) or undergoes plastic deformation before failure (ductile materials).

Common Test Modes

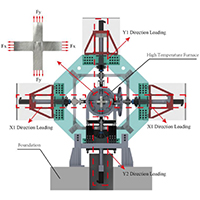

Shear tests are classified by specimen geometry, load application method, and test scenarios, with the following widely used modes:

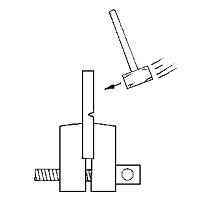

Single shear test: The specimen is loaded along one predefined shear plane, the simplest and most common mode for materials like metals, plastics, and fasteners (e.g., bolts, rivets).

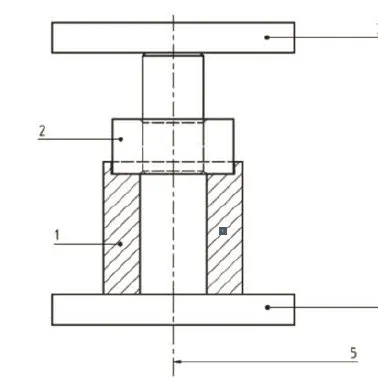

Double shear test: The specimen is supported at two points and loaded centrally, creating two parallel shear planes. This mode is suitable for high-strength materials and components, as it distributes load evenly and reduces stress concentration.

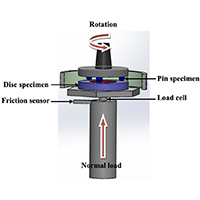

Torsional shear test: Applies torque to a cylindrical or tubular specimen to induce shear stress uniformly across the cross-section, used to evaluate the shear properties of shafts, wires, and cylindrical components.

Impact shear test: Delivers a sudden, high-speed shear load to simulate extreme conditions (e.g., collisions, explosions), commonly used for aerospace materials, automotive safety components, and military materials.

Adhesive shear test: Specifically designed to assess the shear strength of adhesive bonds between two substrates, critical for evaluating the durability of bonded structures.

Material Shear Failure Modes

Different materials exhibit distinct failure characteristics under shear forces:

Ductile materials (metals, thermoplastics): Undergo significant plastic deformation before shear failure, with the shear plane showing signs of yielding and material flow.

Brittle materials (ceramics, glass, cast iron): Experience minimal plastic deformation, fracturing suddenly along the shear plane with a flat, granular fracture surface.

Composite materials: Shear failure often occurs at the interface between fibers and the matrix (delamination), fiber buckling, or matrix cracking, depending on fiber orientation and interface bonding strength.

Adhesive bonds: Failure can occur in three forms: cohesive failure (within the adhesive itself), adhesive failure (at the interface between adhesive and substrate), or substrate failure (the base material breaks before the bond).