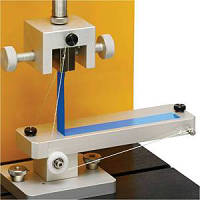

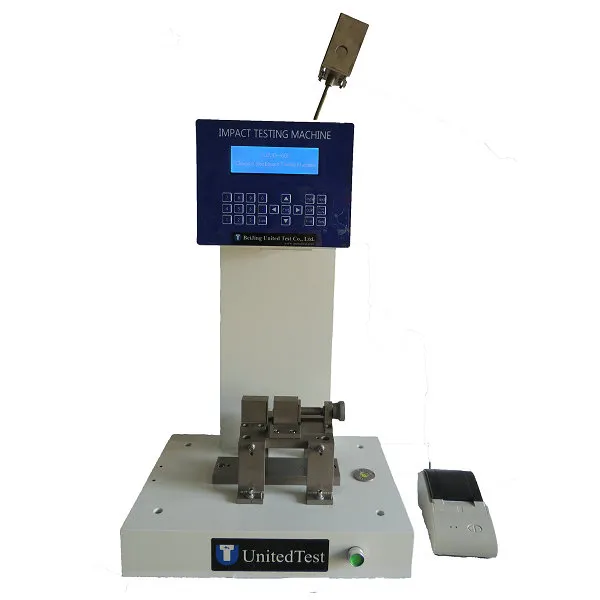

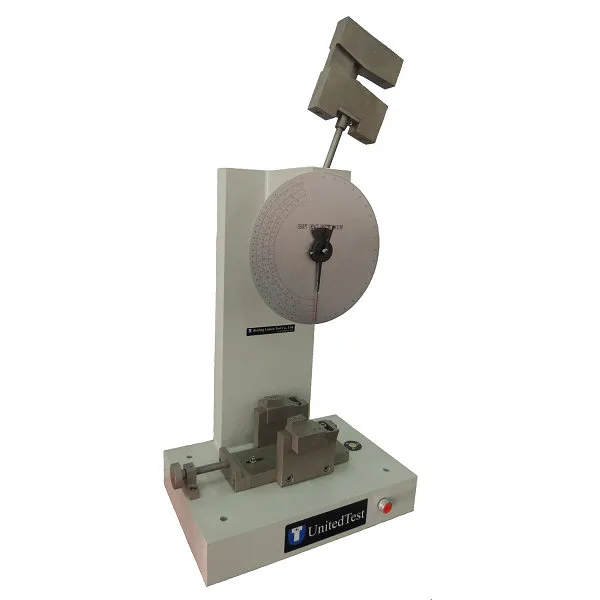

Charpy Test: The specimen is mounted horizontally and supported unclamped at both ends. The hammer is released and allowed to strike through the specimen. If breakage does not occur, a heavier hammer is used until failure occurs.

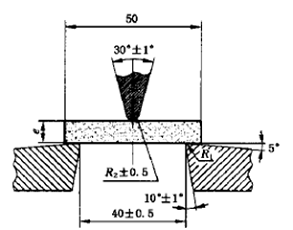

Charpy impact test Specimen size of ISO 179:

Specimens are 80 x 10mm by thickness. The specimens can be either notched or unnotched.

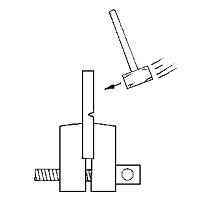

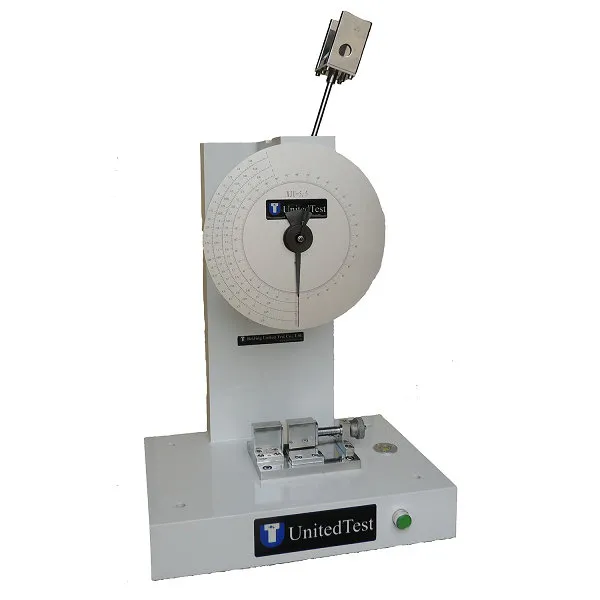

IZOD Test: The specimen is clamped into the pendulum impact test fixture with the notched side facing the striking edge of the pendulum. The pendulum is released and allowed to strike through the specimen. If breakage does not occur, a heavier hammer is used until failure occurs. Since many materials (especially thermoplastics) exhibit lower impact strength at reduced temperatures, it is sometimes appropriate to test materials at temperatures that simulate the intended end use environment.

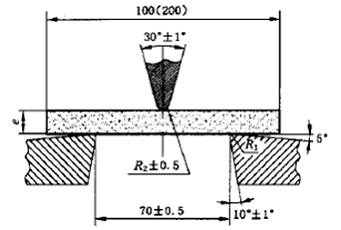

Izod impact test Specimen size of ISO 180:

Thestandard specimen for ISO is a Type 1A multipurpose specimen with the end tabs cut off. The resulting test sample measures 80 x 10 x 4 mm. The depth under the notch of the specimen is 8mm.

ISO 179: “Plastics -- Determination of Charpy impact properties”

ASTM D6110: “Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics”

ISO 180: “Plastics -- Determination of Izod impact strength”

ASTM D256: “Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics”

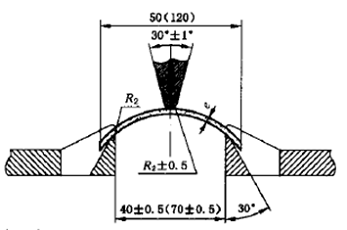

ISO 9854: “Thermoplastics pipes for the transport of fluids -- Determination of pendulum impact strength by the Charpy method”

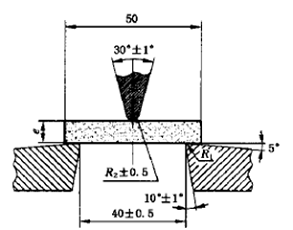

ISO 8256: "Plastic Stretch Impact Intensity Determination" (method A)

ASTM D1822: "Plastic And Electric insulation Material Stretch Impact Performance test Method".

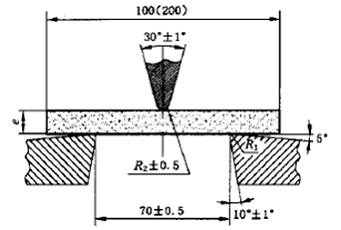

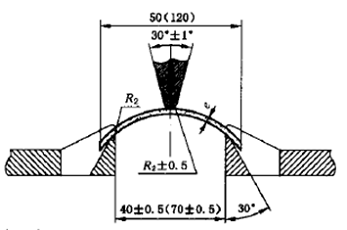

Striking edge & Vice for ISO 9854, pipe impact test.

|  |  |

| Standard bar test piece | Convex test piece | Small bar test piece |