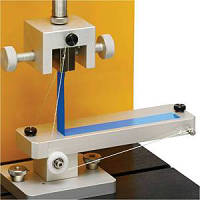

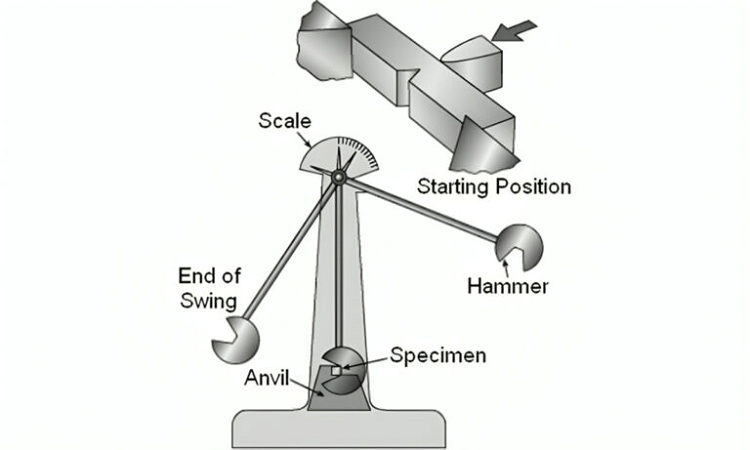

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material's notch toughness and acts as a tool to study temperature-dependent ductile-brittle transition. It is widely applied in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply.

The energy capacity can be from 50J, 150J, 250J, 500J to 750J or even more according customer requirement. With dial display, touching screen type, computer control type etc., can be operated semi-automatically or fully automatic sample feeding. Or Instrumented chieve parameter of Impact velocity, impact time, impact energy, absorb energy, displacement, crack forming energy, crack extension energy, yield load, yield time, peak load, time of peak load, displacement of peak load, energy of peak load, unstable crack extension start load, unstable crack extension stop load, unstable crack extension start energy etc.

Main standard and principle:

The Charpy Impact Test is commonly used on metals, but is also applied to composites, ceramics and polymers. With the Charpy impact test one most commonly evaluates the relative toughness of a material, and as such, it is used as a quick and economical quality control device.

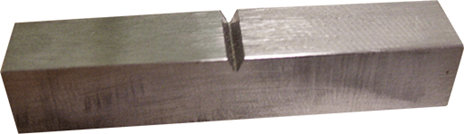

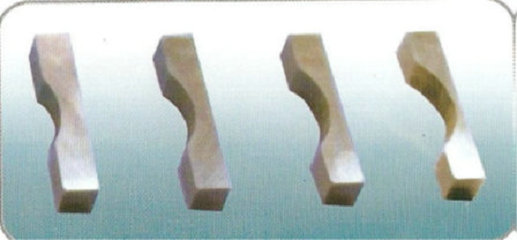

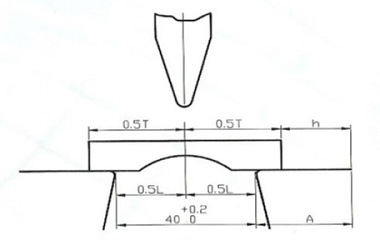

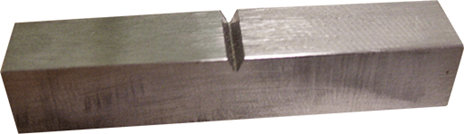

The standard Charpy Impact Test specimen consist of a bar of metal, or other material, 55x10x10mm having a notch machined across one of the larger dimensions.

V-notch: 2mm deep, with 45° angle and 0.25mm radius along the base

U-notch and keyhole notch: 5mm deep notch with 1mm radius at base of notch

Mainly standard:

ASTM E23 “Standard Test Methods for Notched Bar Impact Testing of Metallic Materials”

ISO 148 “Metallic materials -- Charpy pendulum impact test”

BS EN 10045 “Charpy impact test on metallic materials. Test method (V- and U-notches)”

GOST 9454 “Metals. Method for testing the impact strength at the low, room and high temperature”