Powerful and user-Friendly Software and test solution pack.

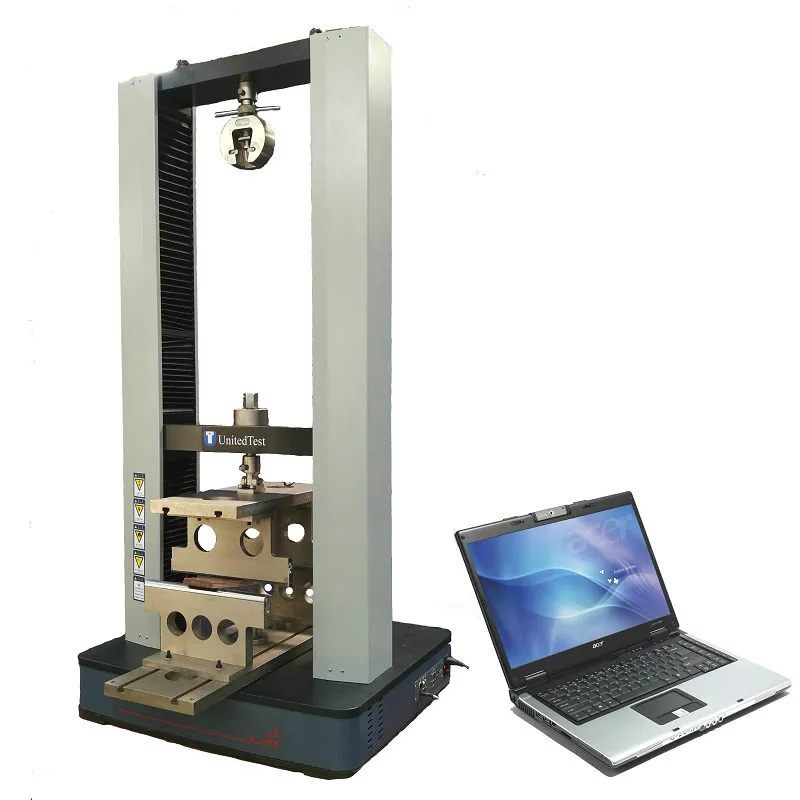

UnitedTest's Fasttest V1.5 is compatible with the full range of UTS universal testing machines. With its ability to adapt to multiple testing scenarios, precise data processing performance, and convenient operation experience, it is widely used in material mechanics testing across industries such as automotive, aerospace, and electronics.

Intuitive and efficient operation experience: It features a workflow-based user interface, with operational logic tailored to the actual habits of testers. From setting test parameters and starting tests to saving data and generating reports, the entire process is clearly guided, allowing both professional laboratory personnel and frontline quality control staff to quickly get started.

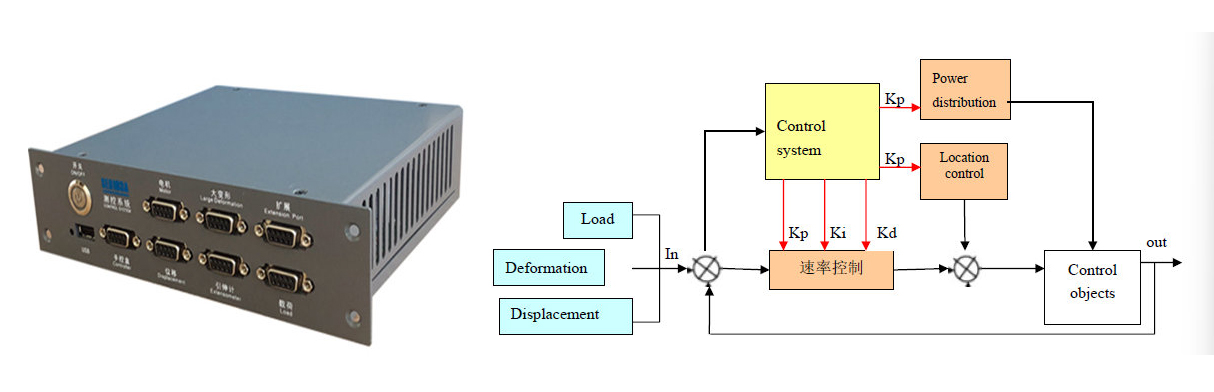

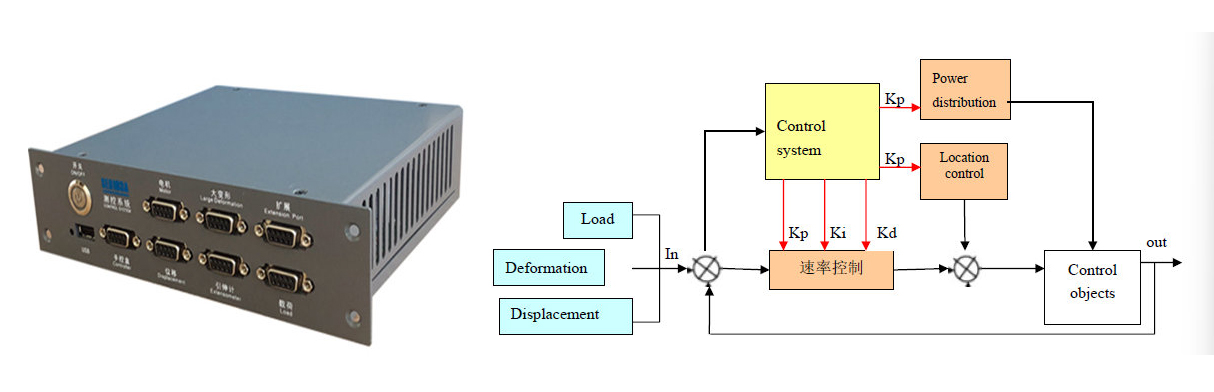

High-precision and highly expandable data acquisition: Paired with the dedicated SED hardware controller, the data acquisition rate reaches 1000Hz, accurately capturing subtle changes in key data such as force and deformation during tests, meeting high-precision testing demands for various materials. The controller also supports plug-and-play expansion modules, allowing up to 14 external channels to be added flexibly according to future testing needs, effectively avoiding equipment obsolescence due to technological updates.

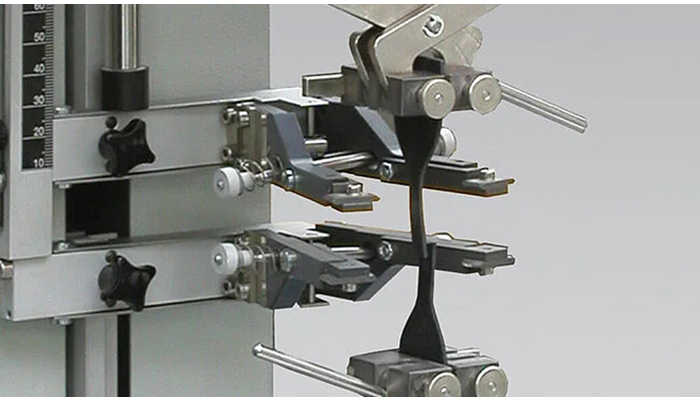

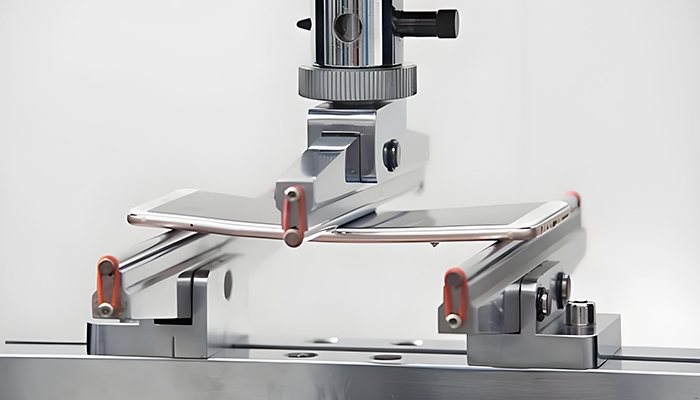

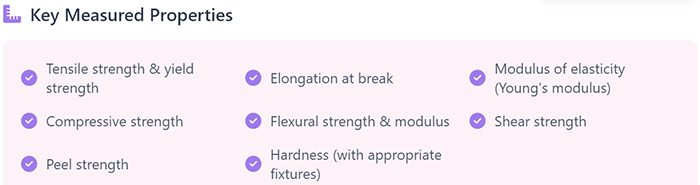

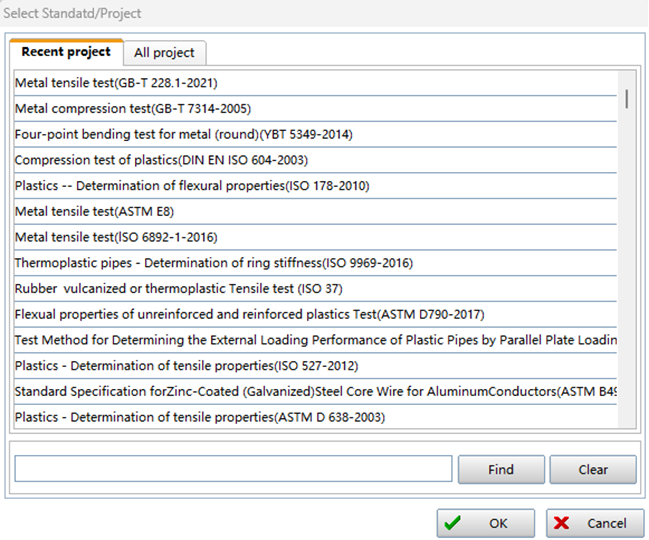

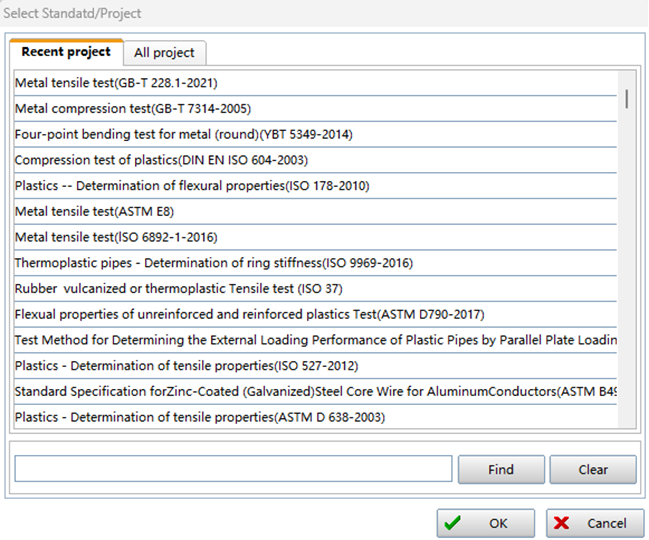

Comprehensive testing and customization capabilities: It includes a built-in library of pre-configured test methods compliant with multiple international and industry standards such as ASTM, ISO, BS, EN, and GB, easily accomplishing various mechanical tests including tension, compression, deformation, and creep failure. Furthermore, users can modify existing test templates or create custom test programs from scratch, accommodating personalized testing requirements for different materials and products.

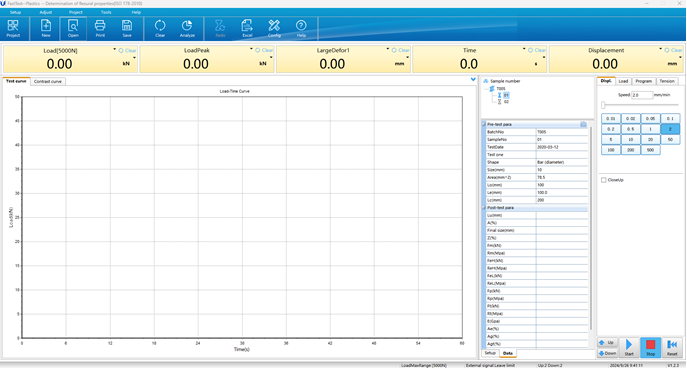

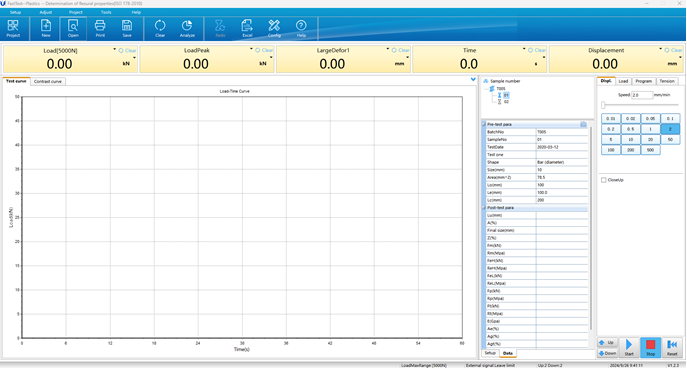

Main interface: Easy to control and friendly interface

(1) Software can esily realize multiple load cells in one load frame; (50KN frame can use like 2KN, 500N load cell etc.)

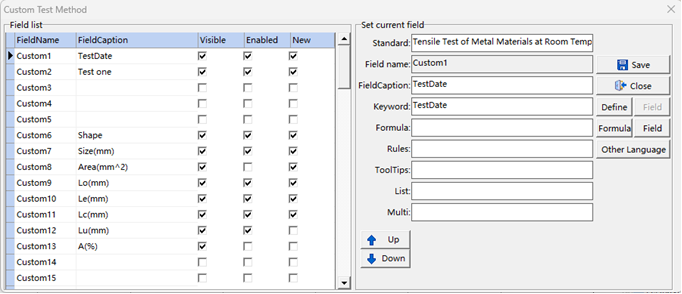

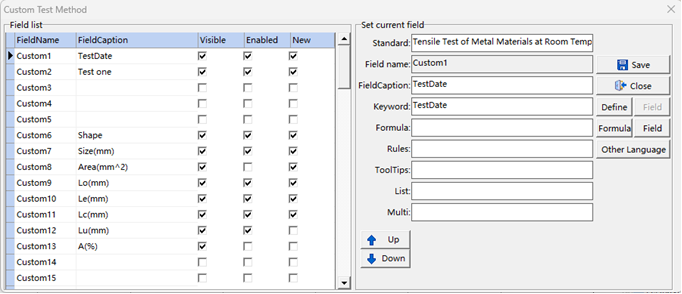

(2) With open program interface, operator can easily customize special test methods

(3) Stepless displaying load value, deformation and peak value, automatic calibration;

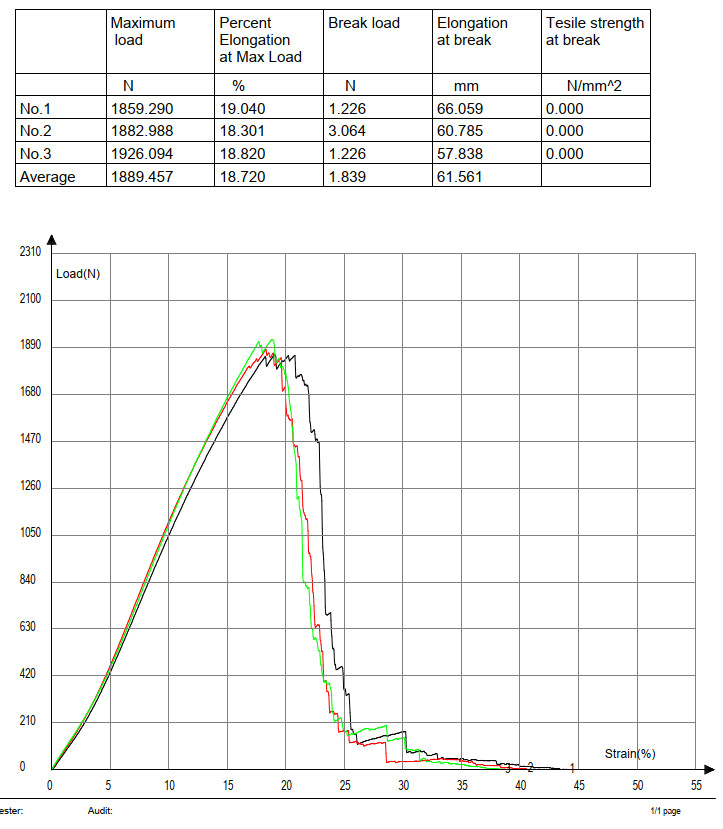

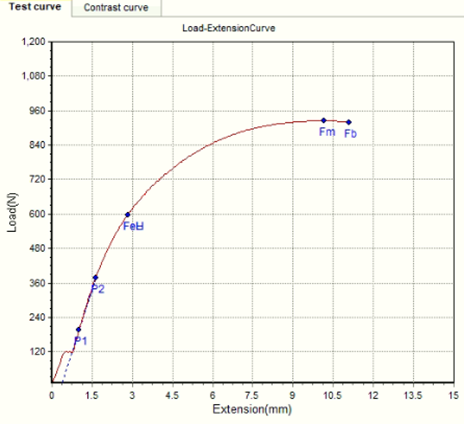

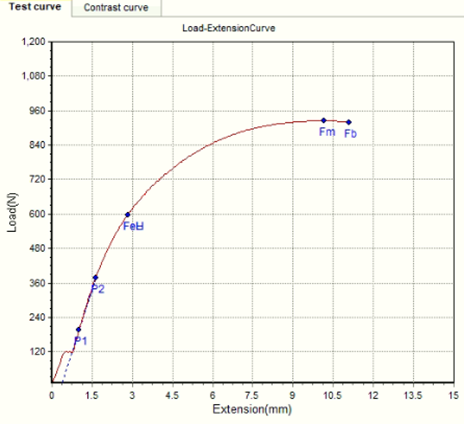

(4) Record and smoothly switch the test curves: Load-Time, Deformation-Time, Load-Deformation and Load-Displacement, sampling quickly;

(5) Interactive mode to analyze and calculate mechanical performance parameter: automatic calculation of elastic modulus, yield strength, non-proportional elongation stress, etc. also with analysis mode of manual intervention to improve accuracy;

(6) With database to manage test data and automatic storage of all test data and curves;

(7) With powerful report editor to edit any forms of reports in short time.

Test Type Selection: Can built-in various test methods according customer requirement.

click Project will show different default test (more than 200 hundreds test Standard include already):

And the test project can be add in future easily by us, or by customer themself.

Customer can custom test method no any restriction:

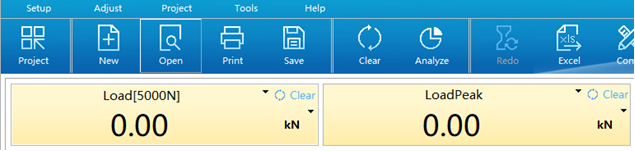

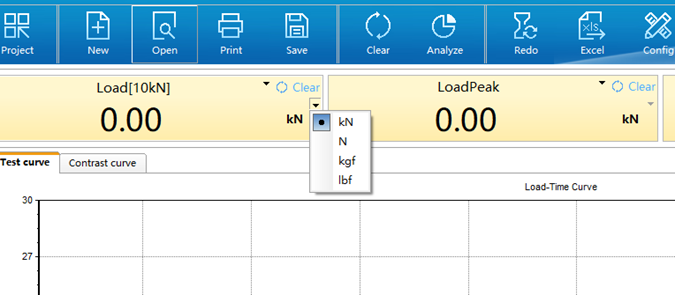

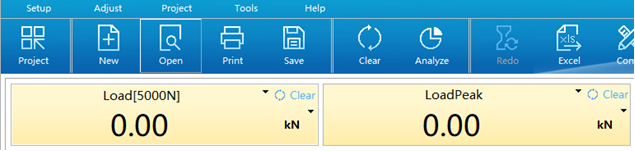

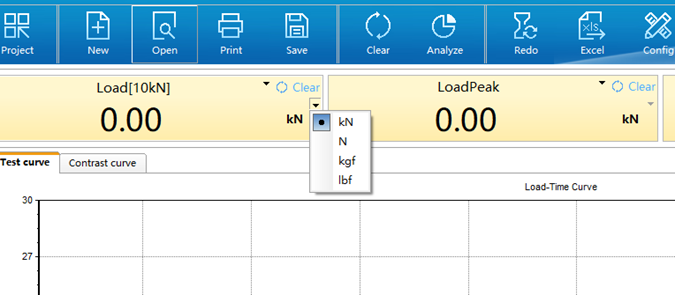

Load/Deformation PANEL

Project: for choose the test methods you need. Clear: to cleat the load, time etc., before test. Down arrow: to choose the other unit like KN, N, kgf, Lbf.

Curve display PANEL, Can choose different curve.

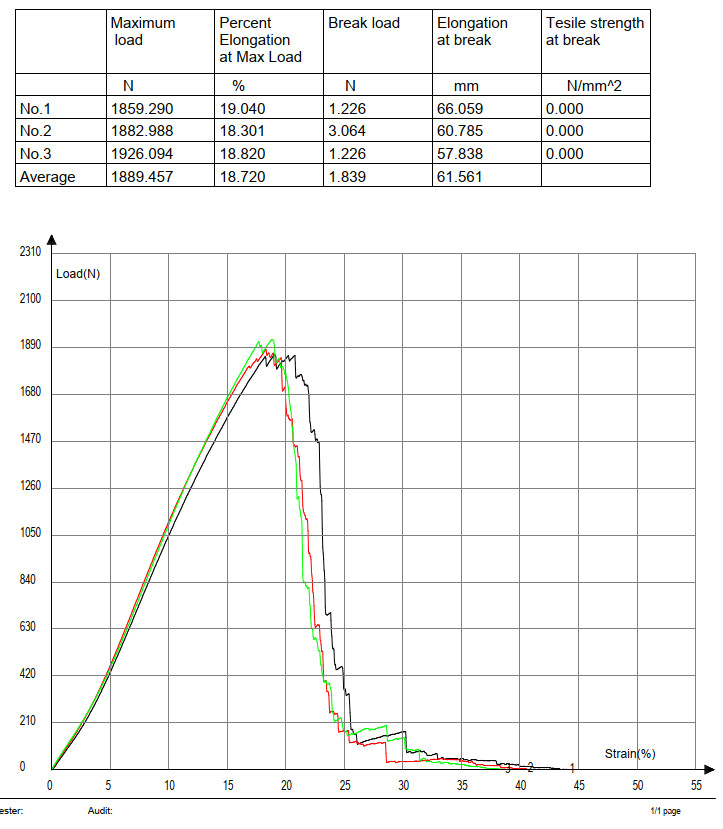

Test Report Editing

Select the item need display and test report;

Edit title, report header, footer etc., choose different curve for the report.

Can save the edition be a template.

The report can be EXCEL.

Test Report