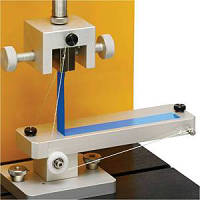

The tear test is a critical mechanical property evaluation method designed to assess a material’s ability to resist the propagation of a pre-existing crack or tear under applied force. Unlike tensile tests that focus on uniform stretching, tear tests simulate real-world scenarios where materials encounter localized damage (e.g., a nick in a film, a cut in fabric) and measure the force required to extend that damage. Key indicators derived from this test include tear strength, tear energy, and tear propagation resistance, which are essential for determining the durability and reliability of flexible and semi-rigid materials. UnitedTest, a professional provider of mechanical testing equipment, offers high-precision tear testing systems with customized fixtures, ensuring accurate and repeatable results for diverse industrial materials.

Core Definition & Principle

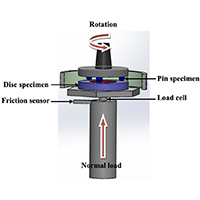

A tear test involves preparing a specimen with a predefined notch or slit (to simulate initial damage) and applying a controlled tensile or shear force to the specimen until the tear propagates completely. The test focuses on two core mechanical behaviors:

Initiation tear strength: The force required to start a tear at the pre-notched area of the material.

Propagation tear strength: The force needed to continue extending the tear through the entire specimen.

The test generates a force-displacement curve, from which tear energy (the total energy absorbed by the material during the tear process) is calculated. This energy reflects the material’s toughness and ability to dissipate energy during damage, making it a key parameter for materials prone to accidental tearing.

Common Test Modes

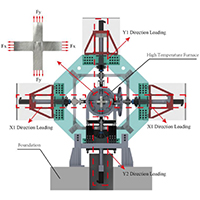

Tear tests are classified by specimen geometry and force application method, tailored to different material properties:

Pendulum tear test: Uses a swinging pendulum to strike the pre-notched specimen, measuring the energy absorbed during tear propagation. Suitable for flexible materials like fabrics, paper, and thin plastics (e.g., the Elmendorf tear test).

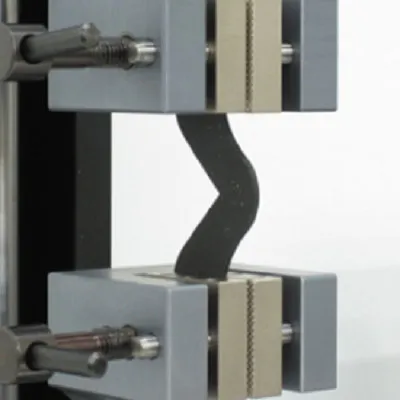

Static tensile tear test: Applies a constant-speed tensile load to a notched specimen (e.g., trouser tear, tongue tear) to control the tear propagation rate. Ideal for rubber, thick plastics, and composite materials.

Impact tear test: Delivers a sudden impact load to the specimen to simulate rapid tearing, commonly used for materials in high-stress applications (e.g., automotive interior fabrics, industrial belts).

Material Tear Failure Characteristics

Different materials exhibit distinct tear behaviors based on their structure and ductility:

Ductile materials (rubber, thermoplastics, woven fabrics): Undergo significant deformation before tearing, with the tear path often deviating slightly as the material stretches, resulting in higher tear energy.

Brittle materials (thin glass films, brittle plastics): Tear propagates rapidly with minimal deformation, often along a straight path, and exhibits low tear strength and energy.

Composite materials (fiber-reinforced plastics, laminated fabrics): Tear behavior depends on fiber orientation and matrix bonding—tear may involve fiber breakage, matrix cracking, or delamination between layers.