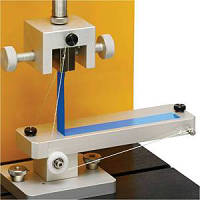

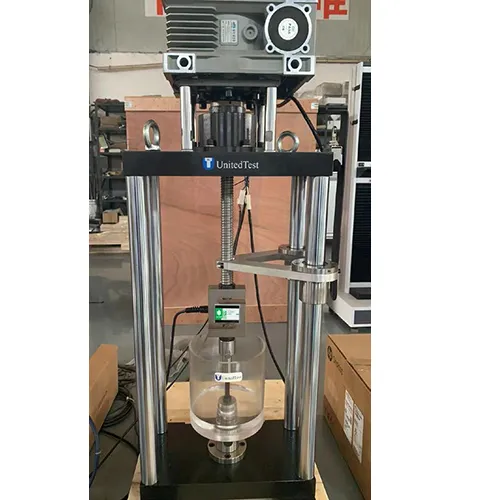

What is Slow Strain Rate Testing (SSRT)?

Slow strain rate testing (SSRT) is a specialized method used to evaluate the corrosion behavior of materials, primarily metals. In this test, a specimen is subjected to elongation at a controlled, constant rate while exposed to specific environmental factors such as corrosive fluids or elevated temperatures. SSRT is also commonly referred to as constant extension rate tensile (CERT) testing.

Understanding SSRT with UnitedTest

Slow strain rate testing provides valuable insights into how materials respond to stress corrosion cracking (SCC) or fracture under particular environmental conditions. The test's accuracy depends on selecting an appropriate strain rate, as rates that are too high or too low may fail to reveal a material’s true susceptibility to cracking.

While a standard strain rate is often applied for testing in different environments, the absence of cracking at that rate does not guarantee immunity. In some cases, SCC susceptibility becomes evident only at higher strain rates. The critical strain rate is defined as the rate at which stress corrosion cracking occurs most rapidly in a given environment. Established standard values exist for critical strain rates for metals such as:

· Stainless steel in chloride or high-temperature water

· Copper and magnesium alloys in nitrite solutions

· Other alloys in specific corrosive environments

Overall, SSRT is an essential tool for mechanistic studies and for assessing the SCC susceptibility of various alloys, making it highly valuable in research and industrial applications.