Oxygen Index (OI) Value refers to the minimum concentration of oxygen required for a material to sustain flaming combustion in an oxygen-nitrogen mixed flow under specified test conditions, expressed as the volume percentage of oxygen.

The oxygen index is a key indicator of a material's combustion performance. The higher the value, the less flammable the material and the better its flame-retardant performance; conversely, the lower the oxygen index, the more easily the material burns. For example, materials with an oxygen index below 21% are considered flammable, while materials with an oxygen index above 27% are generally regarded as flame-retardant.

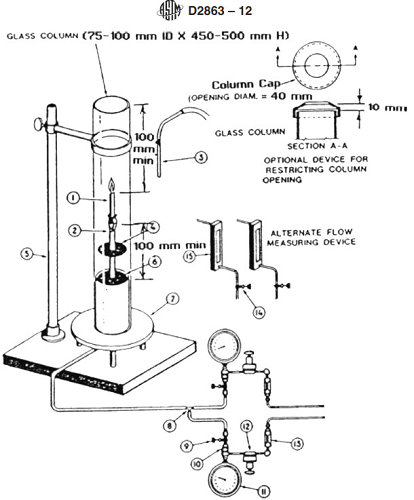

Oxygen index test is a standardized method used to determine a material's oxygen index. This test controls the concentration of the oxygen-nitrogen gas mixture to identify the minimum oxygen concentration at which the material can sustain flaming combustion. Common testing standards include international standards ISO 4589, ASTM D2863.

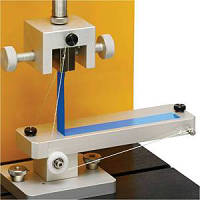

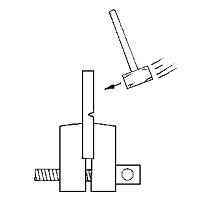

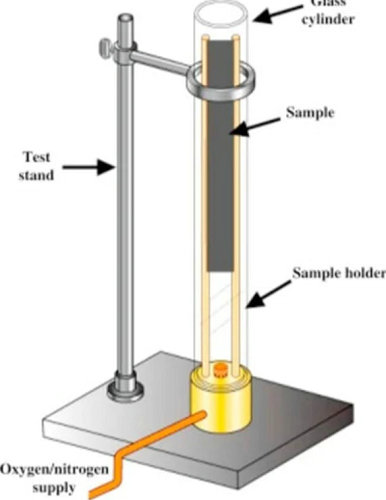

The testing apparatus mainly includes a combustion tube, sample holder, flow control system, and igniter.

Samples are usually held vertically in the combustion tube. After ignition, the oxygen concentration is gradually reduced until the flame goes out, allowing the oxygen index to be calculated.

The oxygen index test has important applications in materials science and engineering, such as evaluating the flame-retardant performance of plastics, rubber, textiles, and aerospace materials, providing a basis for product safety certification and fireproof design. It should be noted that the oxygen index is affected by factors such as temperature, humidity, and material dimensions, so testing conditions must be strictly controlled to ensure accurate results.