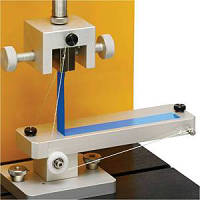

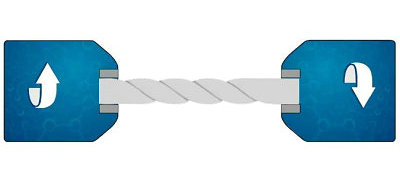

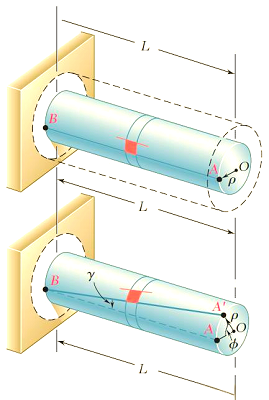

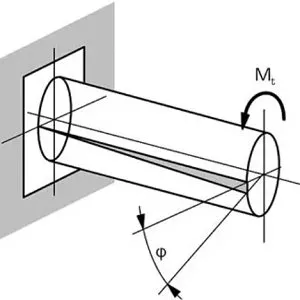

Many materials experience torques or torsional forces in their applications and so will benefit from or require torsion testing. Materials used in structural, biomedical and automotive applications are among the more common materials to experience torsion in their applications. These materials may be composed of metals, plastics, woods, polymers, composites, or ceramics among others and commonly take the forms of fasteners, rods, beams, tubes and wires.

International Standards:

ISO 7800: Specifies static torsion testing methods for metallic materials.

ISO 9649: Metallic Wire Reverse torsion test

ISO 1397: Covers torsion testing of tubes for pressure purposes.

ISO 7206: Implants for surgery — Partial and total hip-joint prostheses — Part 10: Determination of resistance to static load of modular femoral heads — Amendment 1

ISO 6475: Implants for surgery; metal bone screws with asymmetrical thread and spherical under-surface; mechanical requirements and test methods.

ISO 1043: Plastics — Symbols and abbreviated terms — Part 1: Basic polymers and their special characteristics

ASTM A938: Standard Test Method for Torsion Testing of Wire

ASTM F543: Medical Bone Screw Testing

ASTM E143: Standard test method for torsion testing of metallic materials.

ASTM E2207: Standard Practice for Strain-Controlled Axial-Torsional Fatigue Testing with Thin-Walled Tubular Specimens.

ASTM F383: Static Bend and Torsion Testing of Intramedullary RodsISO 80369-7 Small-bore connectors for liquids and gases in healthcare applications Part 7: Connectors for intravascular or hypodermic applications

UNE-EN 1707 CONICAL FITTINGS WITH A 6% (LUER) TAPER FOR SYRINGES, NEEDLES AND CERTAIN OTHER MEDICAL EQUIPMENT. LOCK FITTINGS.

Material-Specific Standards: Separate standards exist for non-metals (e.g., plastics, composites) and components (e.g., fasteners, shafts) to adapt to their unique properties.

Key difference of ASTM A938 and ISO 7800: | Feature | ASTM A938 | ISO 7800 (Metallic Wire – Torsion Test) |

|---|

| Units | U.S. customary primary, SI approximate | SI units (mm, N) primary |

| Test Length | 5 in or 10 in based on diameter | 100 mm or 200 mm based on diameter |

| Tensile Force | Specific lbf values by diameter | Calculated based on wire cross-sectional area |

| Speed Limits | Maximum rpm specified | Rotation speed based on angular velocity (degrees/second) |

| Clamping | Bending ends permitted | No specific mention of end bending |

| Reporting | Emphasizes total turns to fracture | Includes additional torsion stress calculations |