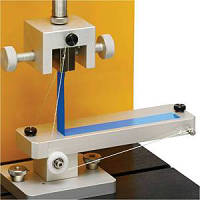

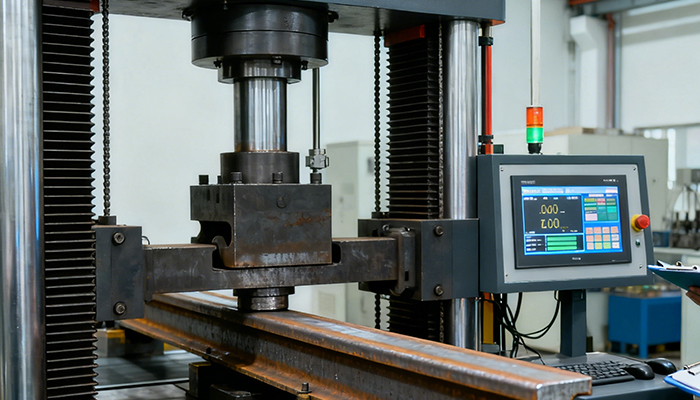

What is the hydraulic universal testing machine?

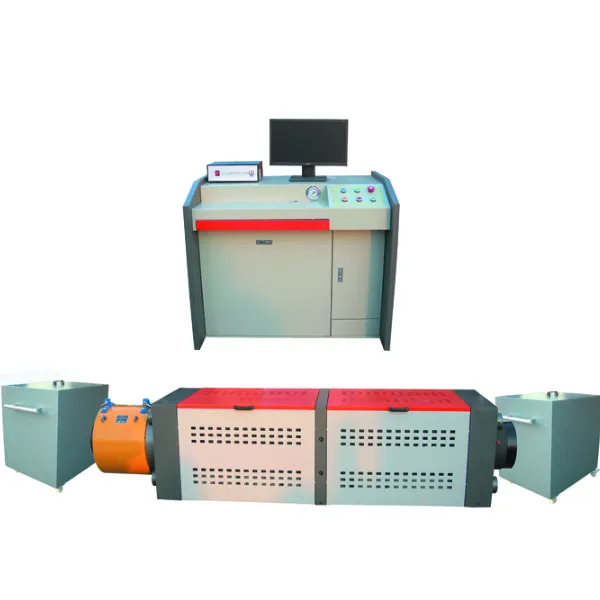

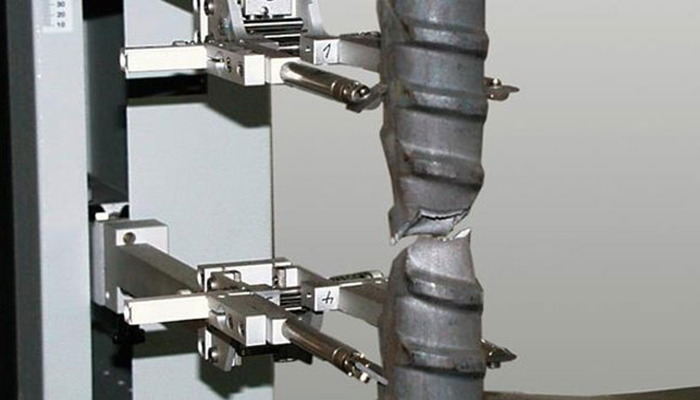

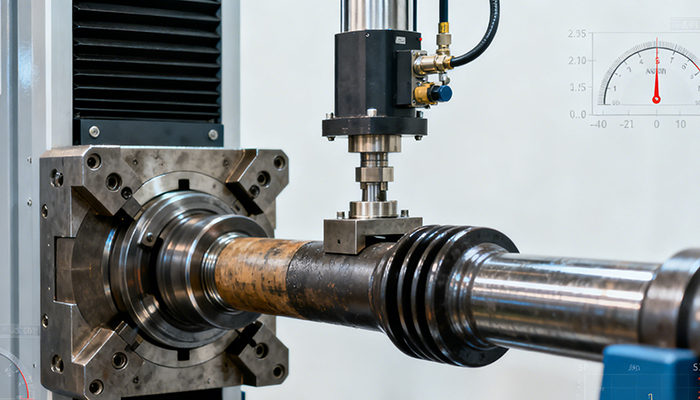

Hydraulic Universal Testing Machine (HUTM) is a high-precision mechanical property testing device based on hydraulic transmission technology. It is capable of performing a full range of mechanical tests (tensile, compression, bending, shear, etc.) on metallic and non-metallic materials, and is widely used in quality inspection, scientific research, and industrial production. Below is a detailed breakdown of its core attributes, supplemented with tables for clarity.

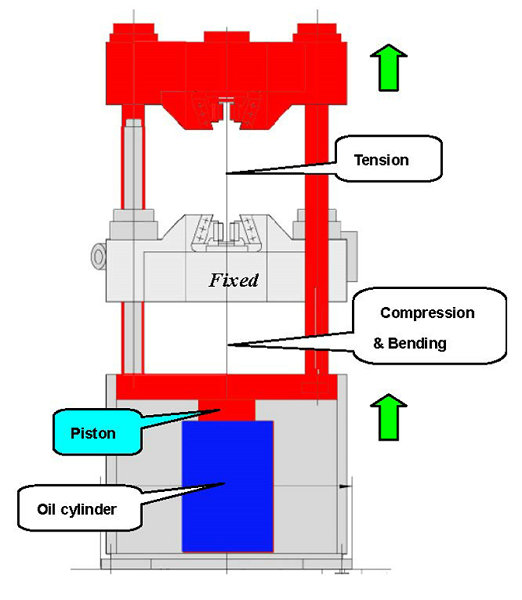

Working Principle

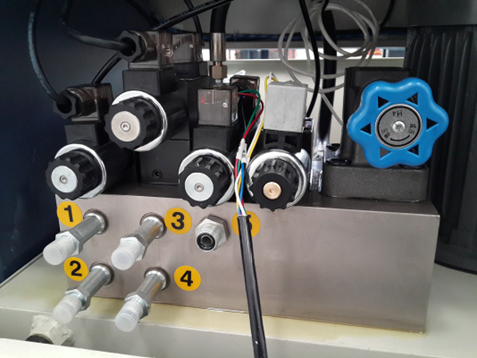

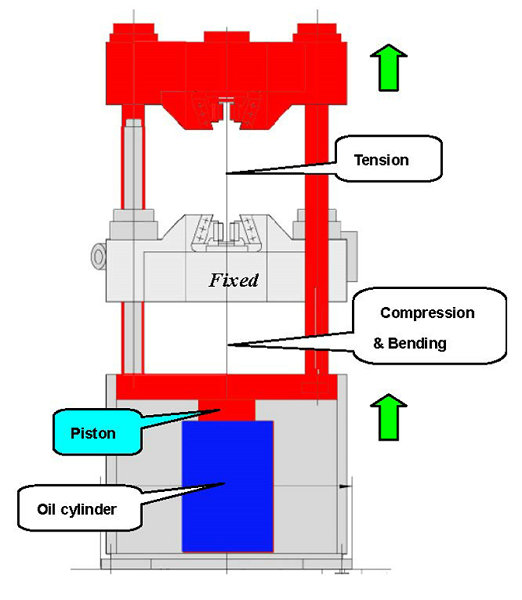

Hydraulic Universal Testing Machine operates on the core logic of "hydraulic transmission + closed-loop control", integrating four key systems to achieve precise load application and data acquisition:

· Power Generation: An electric motor drives a hydraulic pump to convert electrical energy into hydraulic pressure. Hydraulic oil is filtered and delivered to the hydraulic cylinder.

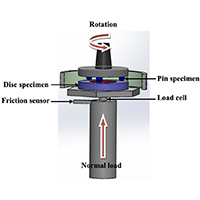

· Load Application: The hydraulic cylinder pushes/pulls the piston to drive the testing machine’s crosshead, and the grippers clamp the specimen to apply tensile or compressive load.

· Closed-Loop Control: A force sensor (load cell) real-time collects load signals and feeds them back to the controller. The controller adjusts the servo valve opening to regulate hydraulic oil flow, ensuring accurate load control (constant load, constant displacement, constant strain).

· Data Acquisition & Processing: Extensometers and displacement sensors measure specimen deformation and piston movement. Signals are digitized and transmitted to an industrial computer, which generates stress-strain curves, calculates mechanical parameters (tensile strength, yield strength, elongation), and stores/test reports.

Advantages and Features

· Single Central Hydraulic Drive: The hydraulic materials testing machines feature a single central hydraulic drive (differential actuator) for precise and reliable force application.

· Adjustable Top Crosshead: Optional adjustable top crosshead allows the test area to be adapted to customer-specific requirements, offering maximum flexibility.

· Ergonomic Design: The machines’ ergonomic operating height ensures easy specimen handling and feeding.

· High-Resolution Measurement: Channel-synchronized, high-resolution measurement technology provides extremely accurate material characterization without the need for range switching.

· Precision Force Measurement: Force is measured via a DMS load cell, calibrated according to ISO 7500-1 Class 0.5 and Class 1 standards, ensuring reliable and repeatable results.

· Wide Measurement Range: The extensive measurement range enables precise determination of low test loads without reconfiguring the machine.

· Stable Installation: Machines are mounted on vibration-damping rubber mats, eliminating the need for a special foundation.