-

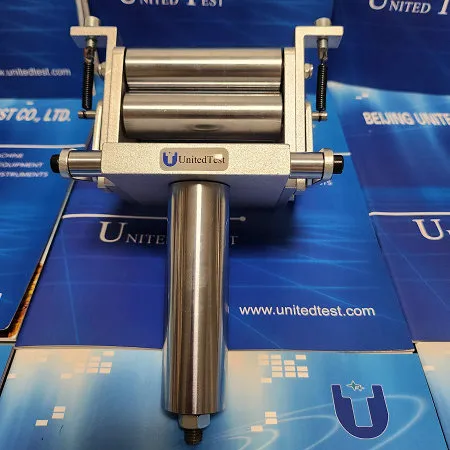

Is your company a trading company or manufacturer?

We are a manufacturer. All testing machines are R&D and Manufactured by UnitedTest with almost 20 years of experience.

-

Do you accept customized services?

Yes, of course, we can not only provide standard machines but also customized instruments according to your requirements and related testing standard.

-

How about your warranty?

Usually, our warranty period is 12 months. During the warranty period, we can provide technical support and parts replacement. We can provide you with lifelong technical support.

-

How about the packaging of the instrument and is it protected during transportation?

Our testing machines are packed in standard export wooden boxes and will not be damaged. We have delivered many test machines abroad by sea or air without damage.

-

What languages does your operating system support?

Our operating systems generally support English. However, we can also offer Russian and other languages upon request based on your specific needs.

-

What are the commonly used trade and shipping terms?

We support various trade and shipping terms, including EXW, FOB, CIF, C&F, DAP, DDU, and DDP. The specific terms will be tailored based on the region, policies, and customer needs.

Payment Terms: We accept multiple payment methods, including T/T, L/C, and Western Union, Paypal.

-

Can you give us the local reference list customer before purchase?

Sure, we can. We have already valuable customer more than 120 countries / regions.

-

Calibration certificate along with the machine will be provided or not?

Yes, all testing machine have our company UnitedTest signed and stamped calibration certificate. If third party certificate from CNAS Lab, need extra cost.

please check CNAS website, this top Chinese National Accreditation Committee for Conformity Assessment. https://www.cnas.org.cn/english/index.html

-

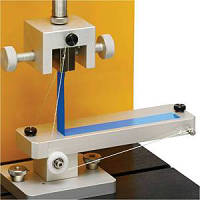

What is the key difference between "Tensile Strength at Yield" and "Tensile Strength at Break," and which is more important?

Tensile Strength at Yield: The stress at which a material begins to deform plastically (permanently). Before this point, the material will return to its original shape when the load is removed (elastic deformation). At and beyond the yield point, the material is permanently stretched. It defines the functional limit for most designs. It's the maximum stress a part can experience in service without being permanently distorted.

Tensile Strength at Break: The maximum stress a material can withstand while being stretched, just before it fractures (breaks). This point occurs aftersignificant plastic deformation (necking). It represents the absolute limit of load-bearing capacity. It's a measure of the material's maximum resistance to failure.

For the vast majority of engineering design (buildings, vehicles, consumer products), Tensile Strength at Yield is the more important property because it defines the safe, functional limit of the material. Tensile Strength at Break is crucial for understanding the failure limit, ductility, and toughness.

-

Why is puncture testing so important for geotextiles?

Puncture resistance is a core mechanical property that directly determines the service life and safety of geotextiles in engineering applications.

In scenarios like roadbed reinforcement, landfill lining, and slope protection, geotextiles are constantly exposed to penetration forces from gravel, soil particles, construction debris, or plant roots. Poor puncture resistance can cause the material to tear or break, losing its functions of filtration, separation, reinforcement, and anti-seepage.

For example, a punctured landfill liner may lead to hazardous waste leakage and environmental pollution; a damaged roadbed geotextile can cause uneven settlement and road cracking.

Puncture test data also provides a scientific basis for material selection, engineering design, and quality acceptance, ensuring geotextiles match the actual working conditions.

-

What's the difference between "Static" and "Dynamic" puncture tests? Which one do I need?

Static Puncture (e.g., CBR/ISO 12236, Index Puncture): Simulates a slow, constant pressure from a blunt object (like a rock under constant load). It measures force required to push a plunger through the fabric at a constant speed. It's used for design against sustained loads (e.g., under a road or landfill).

Dynamic/Impact Puncture (e.g., Cone Drop Test): Simulates a high-energy impact from a falling object (like a tool or rock during installation). It measures the energy absorbed or the size of the hole created by a dropped cone. It's used to assess installation survivability.

You need both. They answer different questions. A product with high static resistance may still tear on impact, and vice-versa. Specifications often require both types of tests.

-

How do I choose the right puncture test for my project specification?

The choice depends on the primary function of the geotextile:

For Protection (e.g., under a geomembrane liner): CBR Puncture (ISO 12236/ASTM D6241) is the primary and mandatory test. It directly simulates a stone indenting the liner system.

For Separation & Stabilization (e.g., under a road base): Often both CBR Puncture (for subgrade stones) and Dynamic Puncture (for installation impact from aggregate) are specified.

For Basic Separation or Filtration: Index Puncture (ASTM D4833) may be sufficient as a general indicator of robustness, but CBR is becoming the industry standard for all heavy civil applications.