Rockwell hardness is a measure of the resistance of a material to permanent indentation under a specific static load. It is defined based on the depth of indentation produced by a penetrator (either a diamond cone or a hardened steel ball) under two sequential loads: an initial minor load and a major load.

Unlike Brinell or Vickers hardness (which rely on indentation area), Rockwell hardness is expressed as a numerical value combined with a scale symbol (e.g., HRC, HRB). The higher the value, the harder the material (with exceptions for some soft materials on specific scales).

Rockwell Hardness Test: Principle

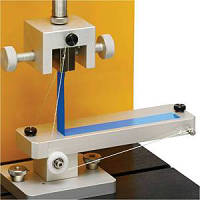

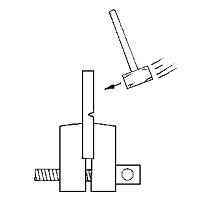

The Rockwell hardness test follows a standardized, four-step process, with its core principle centered on indentation depth difference measurement:

1, Apply initial minor load (preload)

A small fixed load (usually 10 kgf) is first applied to the penetrator. This step eliminates surface irregularities and ensure the penetrator is in stable contact with the test sample, establishing a reference depth position (zero point for depth measurement).

2, Apply major load

After the initial load is stabilized, the major load is added (the total load = minor load + major load). The penetrator presses further into the material, causing plastic deformation.

3, Remove the major load (retain minor load)

The major load is removed, while the minor load remains. The material will undergo elastic recovery, reducing the indentation depth slightly.

Measure the residual indentation depth

The key measurement is the permanent indentation depth increment (denoted as e) after elastic recovery. The Rockwell hardness value is calculated using the formula:

HR=K−0.002e

K = constant (100 for diamond cone penetrators, 130 for steel ball penetrators)

e = residual indentation depth increment (in mm)

The denominator 0.002 means each Rockwell hardness unit corresponds to a 0.002 mm change in indentation depth.

Common Penetrators and Loads (Typical Scales):

Rockwell Scale | Penetrator | Total Load | Application Scope |

HRC | 120° diamond cone | 150 kgf | Hardened steels, alloys (hard materials) |

HRB | 1.588 mm steel ball | 100 kgf | Mild steels, copper alloys, aluminum alloys (medium-soft materials) |

HRA | 120° diamond cone | 60 kgf | Thin hard materials, surface-hardened layers, cemented carbides |