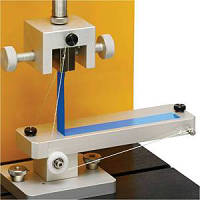

UnitedTest is a world-leading professional supplier of testing equipment for plastics and reinforced plastics. Leveraging years of accumulated manufacturing experience, it provides precise and reliable material testing solutions for various industries. Since its establishment, the company has consistently focused on the field of plastic material testing, making technological innovation its core, deeply cultivating niche markets, and becoming a trusted choice for numerous enterprises, research institutions, and quality inspection agencies.

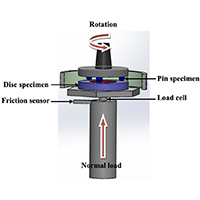

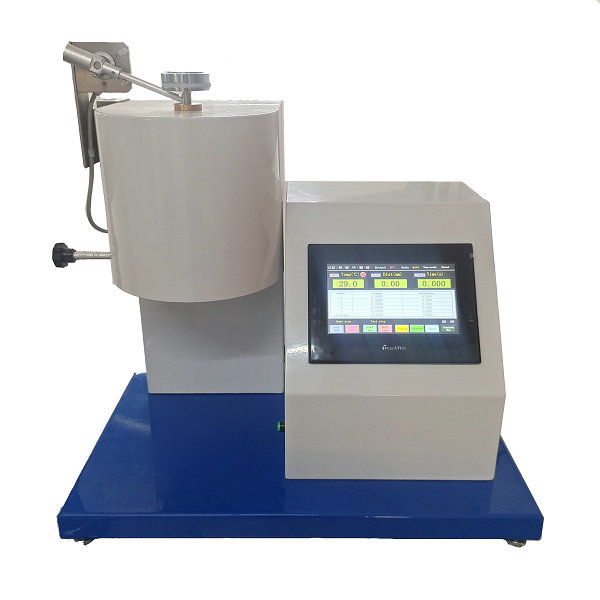

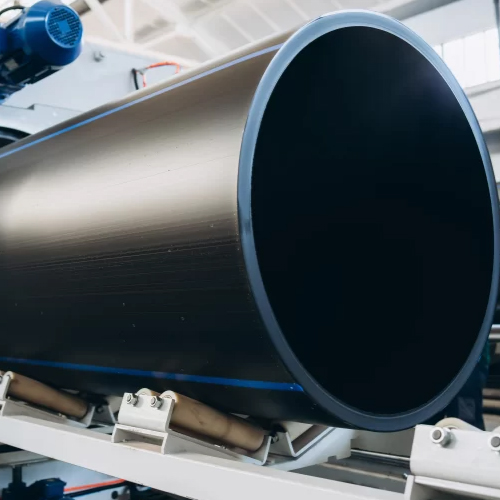

Environmental Stress Cracking ApparatusUnitedTest company's core products cover the full range of testing equipment for plastics and reinforced plastics, including electronic universal testing machines, Pipe Hydrostatic Pressure Testing Machine, Hot cold water thermal cycle testing machine, Piping System Joints Leak Tightness Tester etc., meeting the testing needs of products in different forms such as sheets, pipes, and fiber-reinforced composites. The equipment can accurately perform multiple mechanical property tests, including tensile, compressive, bending, shear, and peel tests, precisely obtaining key parameters such as strength, elastic modulus, and elongation, comprehensively covering the entire process of material R&D, production quality control, and product certification.

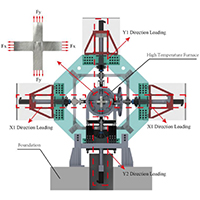

In terms of technical strength, UnitedTest adheres to high-standard manufacturing principles. The equipment uses servo motor drives and precision screw transmission systems, achieving stepless speed regulation from 0.001 mm/min to 2000 mm/min, with a control accuracy of grade 0.5, ensuring the accuracy and repeatability of test data. Furthermore, the products are deeply aligned with international and industry standards such as GB, ISO, ASTM, JIS, DIN, and can provide customized non-standard solutions according to customer requirements, suitable for special testing environments such as high and low temperatures and corrosion.