1. Sample preparation

2. Specimen specifications

Length: 300 mm ± 10 mm, cut flat at both ends and free of defects.

Pretreatment: 23°C±2°C environment conditioning for at least 24 hours to eliminate temperature effects.

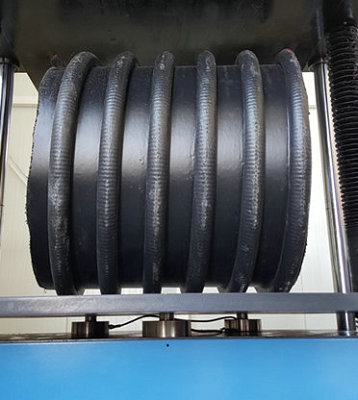

3. Special structural pipe requirements

The corrugated pipe needs to verify the bonding strength between the corrugated layer and the inner wall, and the steel strip reinforced pipe needs to detect the peeling of the steel strip.

Test process

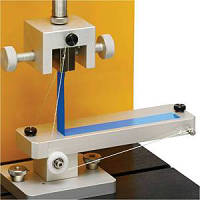

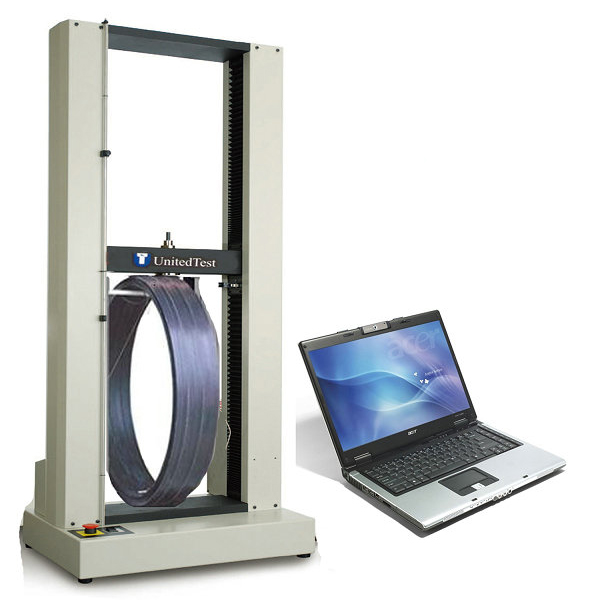

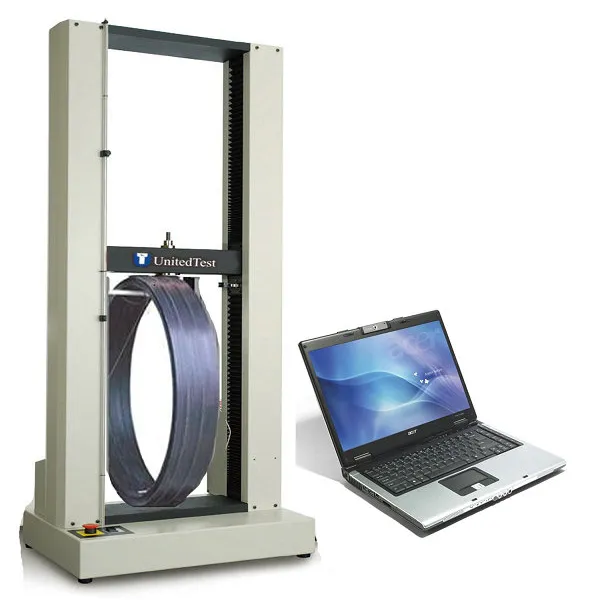

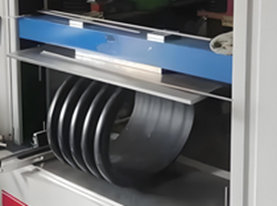

1. Sample installation

Place the specimen horizontally, and the contact surface of the platen at both ends should be parallel to avoid axial displacement.

2. Loading phase

Preloading: Apply an initial load of 50 N to eliminate the gap.

Formal loading: Compressed at a rate of (5±1) mm/min, the force value (F) when the deformation reaches 3% (ΔY=0.03D, D is the initial inner diameter) is recorded.

3. Repeatability verification

The test was repeated after rotation of the same specimen by 90°, and the average of the results was taken twice.

Data processing and calculation

1. Ring stiffness (S) calculation

o Formula: S=FΔY×LS=ΔY×LF (unit: kN/m²), where L is the length of the specimen.

2. Result Judgment If the pipe ruptures before 3% deformation, it is judged to be unqualified, and the material or process problem needs to be investigated.

Related standadrd:

ISO 9969 Thermoplastics pipes -- Determination of ring stiffness

ISO 9967 Thermoplastics pipes -- Determination of creep ratio

ASTM D2412 Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

EN 1446 Plastics piping and ducting systems - Thermoplastics pipes - Determination of ring flexibility

DIN 16961 Thermoplastics pipes and fittings with profiled wall and smooth pipe inside

AS/NZS 1462.22 Methods of test for plastics pipes and fittings Method 22: Thermoplastics pipes – Determination of ring stiffness