Information on the most widely used ASTM standards within the materials testing industry

- Home

-

Products

+

- Universal Testing Machine +

- Dynamic Fatigue Testing Machines +

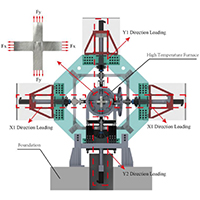

- Biaxial & Triaxial Testing Machines

- Test Fixtures +

- Plastic Pipe Industry Testing +

- Compression Testing Machine +

- Torsion Testing Machine +

- Impact Testing Machine +

- Hardness Tester +

- Industrial Specialized Testing +

- Customized Testing Machine

- Application +

- Technical Support +

- Company

- News +

- Contact