ASTM D6241 Standard Test Method for Static Puncture Index Strength of Geotextiles and Geotextile-Related Products Using a 50 mm Probe.

Core Purpose: ASTM D6241 test method measures the static puncture resistance of geotextiles, geomembranes, and related products. It simulates a scenario where a pointed object (like a rock or root) is pressed slowly against a fabric under constant speed, determining the force required to puncture the material. It is not an impact or dynamic puncture test. which reflects the material's ability to resist multidirectional static penetration from blunt objects like gravel in engineering scenarios.

ASTM D6241 (50-mm probe) is the go-to standard for measuring the static puncture or "CBR" strength of geotextiles. It provides a highly repeatable index value that correlates with a material's ability to resist damage from localized, static pressure from blunt objects. Engineers and specifiers must carefully distinguish it from the smaller-probe ASTM D4833 test, as the two serve different purposes and yield different numerical values.

ASTM D6241 Test Principle:

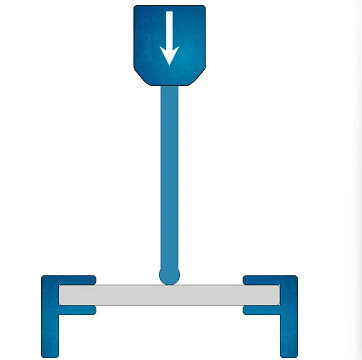

The test simulates a localized, static stress concentration. A circular specimen is securely clamped in a ring without tension. A metal probe with a 50-mm (2-inch) diameter flat end and a 45° chamfered edge is driven perpendicularly through the specimen at a constant speed. The maximum force sustained by the specimen before puncture failure is recorded as the static puncture strength.

Test equipment required for ASTM D6241 puncture test:

| Component | Specification | Purpose |

|---|

| Universal Testing Machine | Constant - rate - of - extension (CRE) type, meeting ASTM D76/D76M; load range ensuring rupture force is 10% - 90% of full - scale load. | Applies a constant speed load and records force - displacement data |

| Probe | A solid, polished steel cylinder with a 50-mm diameter flat end. Polished steel cylinder, ≥150 mm long, radial edge 2.5±0.5 mm; The leading edge has a 45° chamfer (bevel). This specific geometry is critical and distinguishes it from other puncture tests.

| Provides the standard penetration interface |

| Clamping Apparatus | Concentric circular plates with 150 mm inner diameter (unsupported area), external diameter typically 250 mm; anti - slip design (serrated plates, rubber O - rings, etc.), specimen slippage ≤5 mm

| Clamps the specimen without tension to prevent slippage |

| Data Acquisition System | Matched with the testing machine, records peak force and displacement at rupture | Captures and stores test data accurately |

Test Specimen Information:

Size: ≥200 mm × 200 mm (to ensure a 150 mm clamping diameter and sufficient margin for clamping).

Quantity: 10 specimens minimum, cut randomly from different locations of the geotextile roll to ensure representativeness. Five in the machine direction (MD) and five in the cross-machine direction (CD)—to account for material anisotropy.

Conditioning: Specimens are conditioned in a standard atmosphere (e.g., 21±1°C, 60±5% relative humidity) for a sufficient time per ASTM D1776 before testing.

ASTM D6241 Geotextile Punch Test Procedures (Step-by-Step):

| Specimen Preparation | Cut specimens to the required size, avoiding edges and visible defects. |

| Mounting sample | Place the specimen centrally over the 150-mm opening in the lower clamping plate. Secure it with the upper clamping plate, ensuring it is taut and wrinkle-free without prestretching. Mark the test specimen at the inner circumference of the holding container to help measure any potential slippage of the specimen.

|

| Probe Alignment | Position the 50-mm diameter probe concentrically above the center of the specimen. |

| Testing | 1). Select the load range of the tensile testing machine so that fracture occurs between 10% and 90% of the full-scale load. 2). Set the crosshead speed to 50 mm/min, start the test, and drive the probe to penetrate the specimen until rupture. 3). If slippage greater than 5 millimeters is observed, the test of that specimen should be discarded and a new specimen should be obtained. 4). Record the maximum force displayed on the test recorder to determine the puncture strength and displacement. For tests on composite geotextiles, a double peak may occur. If this happens and the second peak is higher than the first, the initial value should also be reported. |

| Data Collection | The machine records the force as the probe deforms and eventually ruptures the specimen. |

| Result Calculation | Calculate the average puncture strength of all valid specimens; discard data if specimen slippage exceeds 5 mm or premature failure due to clamping damage occurs. |

Test Application & Significance:

ASTM D6241 test is crucial for quality control and comparative material selection in geotechnical and environmental engineering. It helps predict performance in real-world scenarios such as:

Protection Layers: Assessing a geotextile's ability to protect geomembranes (in landfills, ponds) from puncture by underlying aggregates or stones.

Subgrade Stability: Evaluating materials used in road bases, railways, and embankments over soft soils where puncture resistance is needed.

Material Specification: Many project specifications and manufacturer data sheets report the "CBR Puncture Strength" (a common name for this test result) as a key index property.

Related Standards:

ASTM D6241 is part of a family of mechanical performance tests for geosynthetics. Key related standards are:

1, ASTM D4833: Standard Test Method for Index Puncture Resistance of Geotextiles, Geomembranes, and Related Products.

Critical Difference: ASTM D4833 uses a much smaller 8-mm diameter cylindrical probe. It measures "index" puncture for thin, flexible materials. D6241 (50-mm probe) is better suited for thicker, nonwoven geotextiles and situations simulating larger, blunt objects. The results from the two tests are not comparable.

2, ASTM D5494: Standard Test Method for the Determination of Pyramid Puncture Resistance of Unprotected and Protected Geomembranes.

Uses a pyramid-shaped probe, specifically designed for geomembranes.

3, ASTM D7518: Standard Test Method for Biaxial Puncture Strength of Geosynthetics.

A more sophisticated test that applies equal pressure in all directions in a plane, simulating a different stress state.

4, ISO 12236: Geosynthetics — Static puncture test (CBR test).This is the direct international equivalent of ASTM D6241, using the same 50-mm probe.

5, EN 15382: A European product standard for geosynthetic barriers that references the CBR puncture test.