ASTM D1599 - 14e1

Standard Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings.

This test method establishes the short-time hydraulic failure pressure of thermoplastic or reinforced thermosetting resin pipe, tubing, or fittings. Data obtained by this test method are of use only in predicting the behavior of pipe, tubing, and fittings under conditions of temperature, time, method of loading, and hoop stress similar to those used in the actual test. They are generally not indicative of the long-term strength of thermoplastic or reinforced thermosetting resin pipe, tubing, and fittings.

Test Procedure

The test comprises two procedures: Procedure A (calculates the specimen’s burst pressure if the failure mode is to be determined) and Procedure B (determines if a specimen complies with a minimum burst requirement).

Procedure A:

The end closures of the specimen are attached and filled with the test fluid maintained at the test temperature. Then, the specimen is connected to the pressurizing device, ensuring that there isn’t any gas trapped inside. The specimen is usually conditioned by dipping in a liquid bath for an hour, at a temperature of 23 +/- 2 °C.. The pressure is increased uniformly and continuously until the specimen fails, and the time required is measured using a stopwatch. If the failure time is less than 60, the loading rate is reduced, and the test is repeated. Note that test failure time for all specimens should be between 60 s to 70 s. Values of applied pressure and time-to-failure are recorded.

Procedure B:

The specimen is prepared in the same way as in Procedure A. The pressure is increased uniformly and continuously, measuring the time along. The minimum burst pressure shall be reached or exceeded between 60 and 70s

This test method is suitable for establishing laboratory testing requirements for quality control purposes or for procurement specifications.

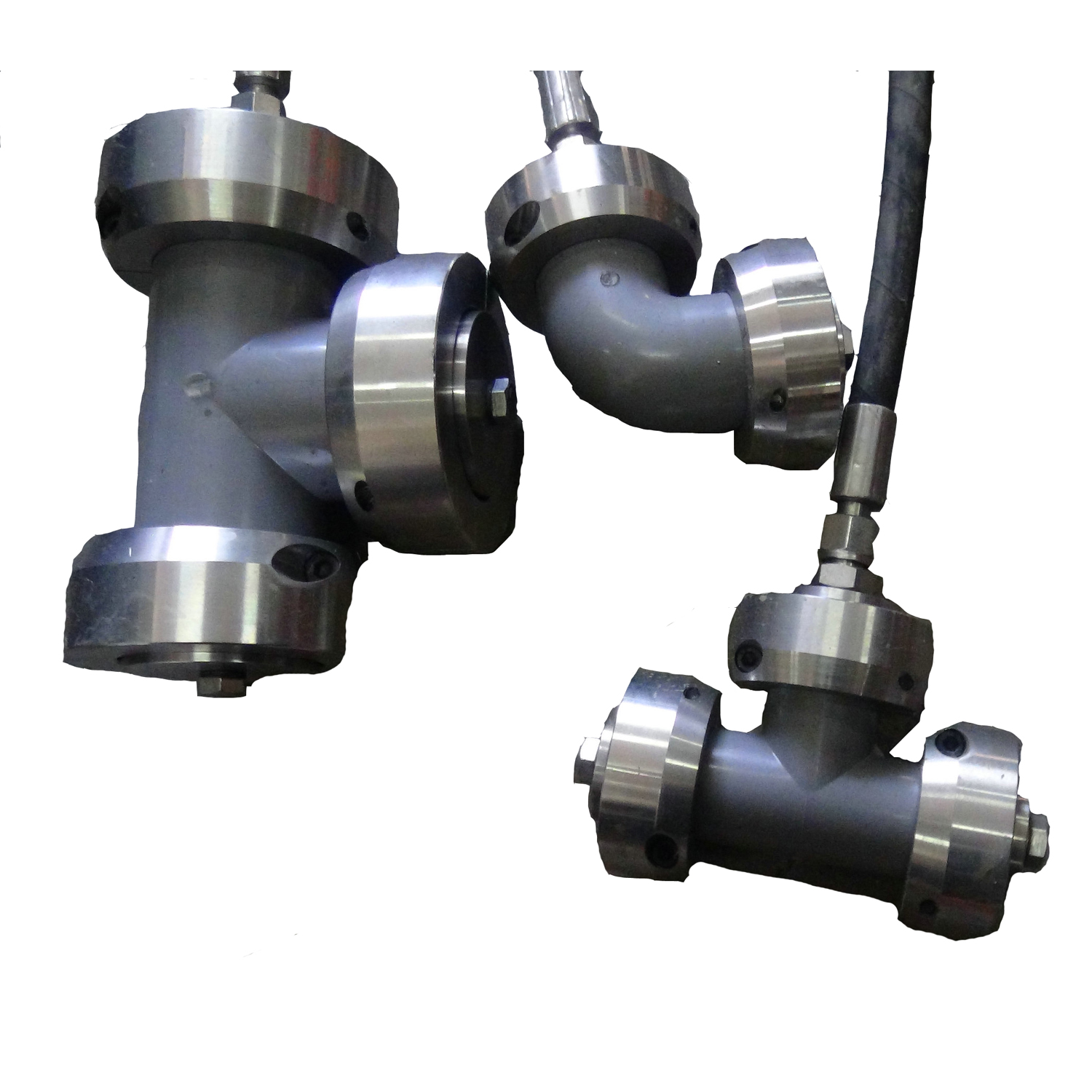

UnitedTest supply the HYD series Pipeline hydrostatic pressure testing machine, according to ISO 1167, ASTM D1598, ASTM D1599. It’s mainly used to test the plastic pipeline, compound pipeline, such as PP-R, PP-B, PP-A, PVC, PE, PE-X etc. Under a stipulated constant hydrostatic pressure force, keeping provision time; or inside the pipe, apply a constant and rapid hydraulic pressure to make the specimen broken in a short period time, check the max. pressure force, then calculate the ring stress. This tester is necessary equipment for plastic pipe manufacturer.

refer product link: Pipe Hydrostatic Pressure Testing Machine.

For more information or details, please contact us:

Email: export@unitedtest.com

whatsapp: +8613911165373