ASTM E328 Stress Relaxation Stress Relaxation Test Equipment for materials and structures, ASTM E328 covers standard testing methods for stress relaxation testing of materials and structures. The stress relaxation of materials is an important characteristic when designing mechanical connectors, which must maintain permanent fastening. If stress relaxation is not considered, long-term failure of the connector may occur. According to ASTM, applications that typically use this standard for testing include: bolt or rivet components, compression fitting of shrink fit fittings, rolling into pipes, tightness of washers, restraining force of springs, and stability of steel wires in prestressed concrete. This test is also applicable for measuring material stress relaxation in high stress concentration areas. The testing environment must be highly controlled to prevent environmental conditions from causing changes to the materials.

Load Application:

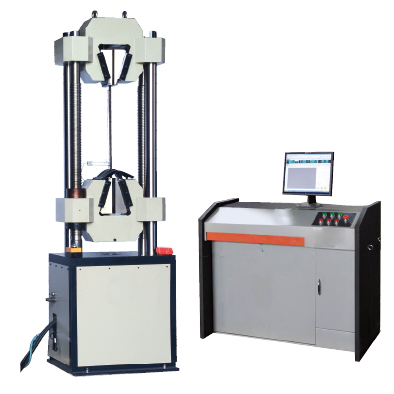

The ASTM E328 method involves preparing the specimen and applying a constant load to it usina a universal testing machine. The decrease in stress within the specimens over time is monitored.

Measurement and Analysis:

The stress relaxation data is recorded as a function of time, strain, or temperature depending on the specific test objectives. The data is then analyzed to determine relaxation modulus, creep compliance, and relaxation time.

Safety and Best Practices in E328 Testing

Testing requires safe handling of materials and equipment especially in high-stress conditions use of PPE, maintenance of the test environment, and reqular maintenance. Proper documentation ensures compliance with industry regulations and traceability.

Importance of E328

It is a critical standard for predicting the long-term service performance of materials and components under continuous stress; ensures product reliability and safety, helps manufacturers select durable materials, improves the quality of products, and facilitates confidence in high-performance industries.