- Universal testing machine

- Fixtures

- Biomedical device/equipment

- Vehicles (car, motorcycle)

- Compression/Flexural test

- Hardness tester

- Impact testing machine

- Torsion testing machine

- Abrasion & wear tester

- Plastic & Pipe testing

- Tensiometer / Goniometer

- Erichsen cupping tester

- Other Testing Equipment

- Grinding & polishing machine

- Introduction

- Specification

- Accessories

- Standard

- LEAFLET & VIDEO

- Contact Us

MMW-1A Vertical Universal Friction Wear Test Machine is similar to an the FALEX MultiSpecimen Test machine in main application and functions, it’s widely used as imitation inspection testing machine in design and develop hydraulic oil, combustion engine oil, gear oil etc..

Perhaps the most versatile commercial system for evaluating friction, wear, and abrasion characteristics of materials, coatings, and lubricants. Numerous Standard Test Methods and Application Specific Custom testing programs are possible due to user selected contact geometries, motions, velocities, temperatures, contact pressures, and test specimen materials allow one test apparatus to meet many test specifications and simulate a broad range of field applications.

Applications include research and development, quality control, product qualification and the evaluation of physical and performance characteristics of materials, coatings, and lubricants. Test studies and a number of technical publications confirm exceptional correlation with field service.

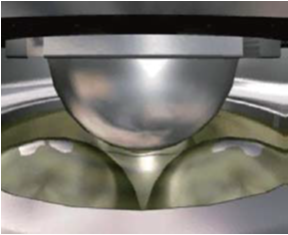

Four ball friction pair Pin-Disc friction pair

Other friction pair like:

Ball-plate friction pair (one ball and three ball);

Bronze ball three pieces of friction pair;

Rolling contact fatigue four-ball friction pair;

Stick-slip friction pair.

| Model | MMW-1A |

| 1 Test Force | |

| 1.1 Axial load range | 10N-1000N |

| 1.2 Load accuracy | ±1% |

| 1.3 Load zero point sensitivity | ±1.5N |

| 1.4 Loading rate | 400N/min |

| 1.5 Load holding accuracy | ±1% |

| 2 Friction Moment | |

| 2.1 Max. Friction moment | 2.5N.m |

| 2.2 Friction moment accuracy | ±2% |

| 2.3 Friction sensor | 50N |

| 2.4 Friction arm of force distance | 50mm |

| 3 Spindle stepless speed change | |

| 3.1 Stepless variable speed system | 5-2000r/min |

| 3.2 Main spindle RPM accuracy | ±1% |

| 4 Test Medium | Oil, Water, Slurry, Abrasive, etc. |

| 5 Heating system | |

| 5.1 Heater working range | Ambient temp. to 260℃ |

| 5.2 Disc Type Heating Plate | φ65, 220V, 250W |

| 5.3 Jacket Heater | φ68×44,220V,300W |

| 5.4 φ3 twin output platinum thermal resistance | RO=100±0.1Ω(Long, short each one set) |

| 5.5 Temperature control accuracy | ±(0.3+0.005t)℃ |

| 6. Taper of spindle | 1:7 |

| 7. Max.distance between spindle and lower disc | >75mm |

| 8. Spindle control | 1, Manual control; 2, Time control ; 3, Revolution Control; 4, Friction moment control |

| 9. Time display & control range | 10s~9999min |

| 10. Revolution display & control range | (1~99)×105 |

| 11. Output maximum moment of main motor | 5N.m |

| Dimensions | 860*740*1560mm |

| Weight | 650Kg |

| Item | Quantity |

| Frame | 1 set |

| Computer | 1 set |

| Printer | 1 set |

| Thrust ring end face friction test pair | 1 set |

| Pin-disc friction test pair | 1 set |

| Four ball friction test pair | 1 set |

| Ball disc friction test pair | 1 set |

| Heater | 1 set |

| Microscope | 1 set |

| Professional measuring software in English | 1 set |

| Documents (Manual, packing list, certificate) | |

ASTM G99 "Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus”

ASTM D2266 "Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four Ball Method) “

ASTM D4172 “Standard Test Method for Wear Preventive Characteristics of Lubricating Fluids (Four Ball Method)”

ASTM D3702 “Standard Test for Wear Rate and Coefficient of Friction in Self-Lubricated Rubbing Contact Using a Thrust washer Testing Machine”

Global links

Global links